-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Pre-Roll Boxes Wholesale: Custom Design Trends, Branding & A/B Testing for Maximum ROI

Pre-Roll Boxes Wholesale: Custom Design Trends, Branding & A/B Testing for Maximum ROI

I’ve spent years working with cannabis brands and dispensaries, and I can tell you this: your pre-roll boxes are doing way more heavy lifting than you think. They’re not just compliance vessels or protective packaging—they’re miniature billboards, brand ambassadors, and conversion tools all rolled into one. When you’re ordering pre-roll boxes wholesale, the stakes get even higher because you’re committing to volume, and that means every design decision impacts your bottom line at scale.

[rank_math_toc]

The problem? Most brands treat wholesale packaging like a checkbox exercise. They nail the compliance requirements, pick some colors, slap on a logo, and call it done. Meanwhile, their competitors are systematically testing packaging variables, adapting designs for different sales channels, and treating their boxes like the strategic assets they actually are.

We’re going to change that. This isn’t another surface-level post about making your boxes “look pretty.” We’re diving into the mechanics of maximum ROI—channel-specific adaptations, realistic printing specifications, systematic A/B testing frameworks, and a modular design philosophy that lets you optimize without burning through your entire packaging budget every quarter. Let’s get into it.

Why Pre-Roll Box Design Actually Matters to Your ROI

Look, I get it. You’re running a business, not an art gallery. But here’s the reality: in dispensaries where customers face walls of nearly identical products, your packaging is often the only thing speaking for you. The budtender might recommend you, or they might not. Your product might be superior, but if the box doesn’t communicate that in three seconds or less, you’ve lost the sale.

The ROI connection is direct. Better packaging drives higher conversion rates at point-of-sale. Higher conversions mean better velocity. Better velocity means more reorders from dispensaries. More reorders mean you can negotiate better terms with your wholesale printer and improve your margins. It’s a flywheel, and packaging design is the initial push that gets it spinning.

I’ve seen brands increase their dispensary placement success rate by 40% simply by redesigning their wholesale packaging to better communicate strain benefits and brand personality. That’s not magic—that’s strategic design meeting buyer psychology.

The Three-Second Shelf Test

Here’s an exercise I recommend to every client: walk into a dispensary, stand in front of the pre-roll section, and give yourself three seconds to decide which product you’d buy based solely on packaging. Three seconds. That’s generous, honestly—most customers decide faster.

What catches your eye? What communicates quality? What feels premium versus bargain-bin? Your wholesale pre-roll boxes need to win this test consistently because that’s the real-world environment they’ll live in. Multiply those individual conversion moments across dozens of dispensaries and thousands of customer interactions, and you start to see how design directly impacts revenue.

Custom Design Trends That Actually Drive Sales

Trends are tricky in cannabis packaging because what’s trendy isn’t always what sells. I’ve watched brands chase aesthetic trends that looked gorgeous on Instagram but tanked on shelves because they didn’t communicate product benefits or brand positioning clearly. The sweet spot? Trends that align with consumer purchase psychology and brand differentiation needs.

Minimalism with Strategic Information Density

The minimalist trend isn’t going anywhere, but here’s the nuance: successful minimalist pre-roll packaging isn’t just white space and a logo. It’s strategic reduction—eliminating visual noise while amplifying the information that actually drives purchase decisions. Think strain name, THC percentage, and one compelling benefit or experience descriptor, all presented with breathing room.

We’re seeing brands use oversized typography for strain names, making them readable from six feet away. That matters when customers are scanning shelves quickly. The minimalism creates sophistication and premium positioning, but the information hierarchy ensures functionality isn’t sacrificed for aesthetics.

Strain-Specific Color Coding Systems

This is huge for brands with multiple SKUs. Instead of making every box look identical except for tiny text variations, develop a color system that customers can learn: deep purples for indicas, bright greens for sativas, sunset oranges for hybrids. Once dispensary customers recognize your system, they can spot their preferred strain type instantly, even from across the store.

The ROI here is repeat purchase velocity. Loyal customers spend less time searching and more time buying. They also recommend your products more confidently because they can easily direct friends: “Look for the purple box from Brand X.” That’s organic brand-building through packaging architecture.

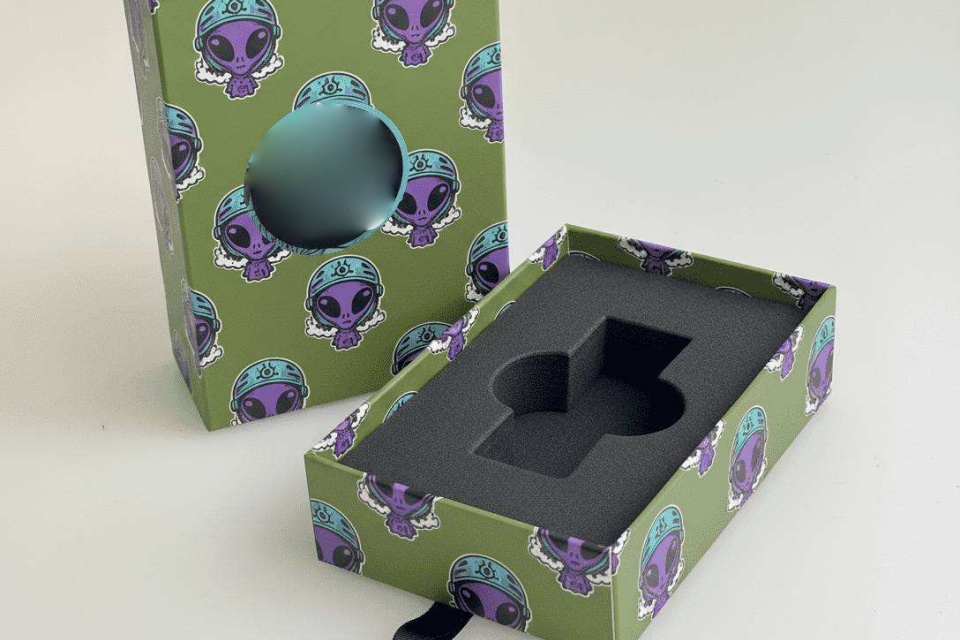

Texture and Finishing for Tactile Differentiation

Don’t underestimate touch. When a customer picks up your box, what do they feel? Soft-touch lamination, spot UV gloss on logos, embossing—these finishing techniques create a premium tactile experience that budget packaging can’t match. The psychological impact is real: premium feel equals premium product assumption.

From a wholesale perspective, these finishes do add cost, but the margin improvement from premium positioning typically outweighs the additional expense. I recommend running calculations: if soft-touch coating adds $0.15 per box but lets you charge $2 more per unit, that’s profitable differentiation.

Channel-Specific Design Adaptations That Most Brands Miss

Here’s where most packaging strategies fall apart: brands create one design and try to force it to work everywhere. Retail shelves, e-commerce, subscription boxes—these channels have completely different requirements. Your wholesale ordering strategy should account for this.

Retail Dispensary: Vertical Shelf Optimization

In dispensaries, your boxes usually sit vertically on shelves, meaning the face panel needs to work vertically too. I see so many brands design horizontally-optimized graphics that look awkward when displayed properly. Visit the dispensaries carrying your product. Photograph your packaging in situ. Does your brand name read clearly? Is key information visible, or is it hidden by the shelf edge?

Consider ordering a portion of your wholesale run with shelf-optimized layouts: vertical text orientations, top-panel information for downward viewing angles, and front-panel designs that work in narrow shelf depths. Some of my clients run 70% standard and 30% shelf-optimized variants, allocating the optimized versions to high-traffic retail accounts.

Online/Delivery: Photography-First Design

When your product is photographed for online menus, different elements matter. High contrast works better in photos. Clear text reads better in compressed images. Visual complexity that looks sophisticated in-hand can look muddy in a 200×200 pixel thumbnail.

If 40% of your sales come through online ordering, consider a wholesale packaging variant optimized for digital photography: bolder graphics, higher contrast, simplified elements. This isn’t about creating completely different branding—it’s about adapting your core design system for the medium.

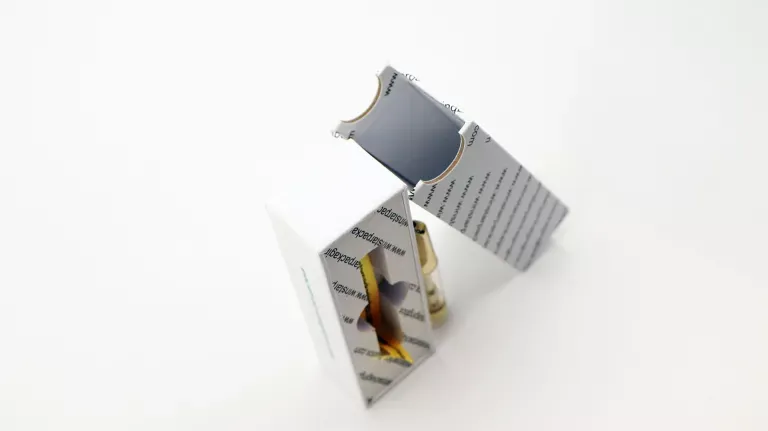

Subscription Boxes: Unboxing Experience Design

Subscription customers engage with packaging differently. They’re not making split-second shelf decisions—they’re having a planned, often ritualistic unboxing experience. These boxes can carry more information, tell deeper brand stories, and include elements that reward close inspection: hidden messages, inside-panel printing, sequential designs that change each month.

The ROI mechanism here is retention and social sharing. Great unboxing experiences get photographed and shared. Subscription customers who feel delighted stay subscribed longer. When ordering wholesale, allocate a smaller run of subscription-specific designs with enhanced finishing and storytelling elements.

Realistic Wholesale Printing Specs and Cost Optimization

Let’s talk practical manufacturing reality. I’ve seen brands design spectacular packaging that their printer can’t actually produce, or can produce only at prohibitive costs. Understanding wholesale printing constraints up front saves you from expensive redesigns and delays.

Minimum Order Quantities and Strategic Planning

Most wholesale packaging printers have MOQs between 1,000 and 5,000 units per design. That’s not per color variant—that’s per exact specification. Want to test three color variations? You might need to order 3,000 units minimum. This is where strategic planning becomes critical.

I recommend a portfolio approach: order your core design in maximum quantity to get the best per-unit pricing, then order smaller quantities of test variants through short-run digital printing services. Yes, the per-unit cost is higher on short runs, but the ability to test without massive commitment is worth the premium. Once testing identifies winners, roll them into your main wholesale orders.

Material Choices and Their Real-World Trade-offs

SBS (solid bleached sulfate) paperboard is the industry standard—it prints beautifully and has good structural integrity. But don’t ignore alternatives. Kraft paper creates an organic, eco-friendly aesthetic that resonates with certain demographics. Metalized boards create premium shimmer but can make text legibility challenging.

Here’s what I actually recommend for most brands starting wholesale orders: 18pt SBS with a C1S (coated one side) finish for the exterior. This provides excellent print quality while managing costs. Add soft-touch lamination and spot UV selectively—maybe just on logos and key design elements rather than full coverage. This gives you premium tactile differentiation at a fraction of the cost of full coverage.

Color Matching and Consistency Across Runs

This frustrates brands endlessly. You approve a proof that looks perfect, then your first wholesale run arrives and the colors are… off. Not wildly off, but enough to bother you. Here’s the reality: color variation between runs is normal in offset printing. The question is keeping it within acceptable tolerances.

Specify Pantone colors for brand-critical elements rather than relying on CMYK process colors. Pantone matching is more expensive but delivers consistency across runs. For less critical design elements, CMYK is fine. Work with your printer to establish acceptable variation ranges in your initial agreement. Request press checks for large runs where you or a representative can approve colors on-press before the full run completes.

Systematic A/B Testing Frameworks for Packaging

Here’s where we separate sophisticated brands from everyone else. Most companies redesign packaging based on gut feelings, designer preferences, or founder opinions. Smart brands test systematically and let data drive decisions. The ROI improvement from optimization can be substantial—we’re talking 15-30% sales increases from packaging changes alone.

Setting Up Valid Packaging Tests

Packaging A/B testing isn’t as simple as website testing. You can’t instantly switch what a customer sees. You need to design tests that account for physical distribution realities while still producing valid data. Here’s the framework I use:

First, identify your testing variable. Don’t test multiple changes simultaneously or you won’t know what drove results. Test one thing: color, imagery style, information density, finishing technique, whatever you’re most curious about. Create two variants that differ only in that variable.

Second, establish matched distribution. Split your wholesale order between variants and distribute them to matched dispensary accounts—similar size, similar demographics, similar traffic patterns. If you put variant A in all your premium locations and variant B in your struggling accounts, your data will be meaningless.

Third, track sales velocity at the account level over a meaningful timeframe—at least 30 days, ideally 60. You’re looking for statistically significant differences in sell-through rates between variants. Account for external factors: promotions, budtender training, product placement changes during the test period.

What to Test and Why

Not all packaging variables deserve testing. Focus on elements that plausibly impact purchase decisions. Here are the highest-ROI testing priorities I recommend:

Color dominance: Does a predominantly green box outsell a predominantly black box for the same strain? Color psychology is powerful but brand-specific. Test within your context.

Information presentation: Does emphasizing THC percentage drive more sales than emphasizing experiential descriptors (“relaxing,” “creative,” “energizing”)? Different customer segments respond to different information.

Imagery vs. graphics: Do photography-based designs outperform illustration or abstract graphics? This often segments by price point—premium products often benefit from sophisticated graphics, value products from clear photography.

Finishing presence: Does soft-touch lamination justify its cost with higher sales velocity? Does spot UV increase perceived value enough to drive purchase preference? These are quantifiable questions with data-backed answers specific to your brand.

Interpreting Results and Scaling Winners

Let’s say your test concludes and variant A outsold variant B by 22% across matched accounts. Don’t immediately redesign everything. First, validate the result wasn’t a statistical fluke—maybe one variant benefited from random external factors. Consider a follow-up test with swapped distribution if results seem too good to be true.

Once confident, scale the winning variant into your core wholesale orders. But keep the testing infrastructure in place. Packaging optimization isn’t a one-time project—it’s an ongoing process. Your next test might explore refinements to the winning design, or adaptations for new product lines, or channel-specific variants.

The brands winning in cannabis aren’t necessarily those with the biggest budgets or most talented designers. They’re the ones systematically improving through testing, treating packaging as a lever they can pull to impact revenue.

Modular Pre-Roll Box Design Systems

Now we get to the big idea that changes how you think about wholesale packaging investment: modularity. Instead of designing each new product line or seasonal release from scratch, you build a design system with interchangeable components. This dramatically reduces costs, speeds up time-to-market, and creates powerful brand consistency.

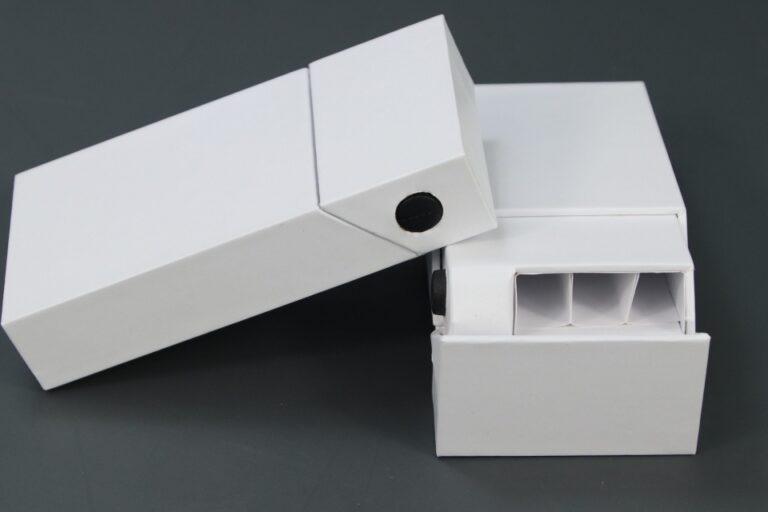

What Modular Design Actually Means

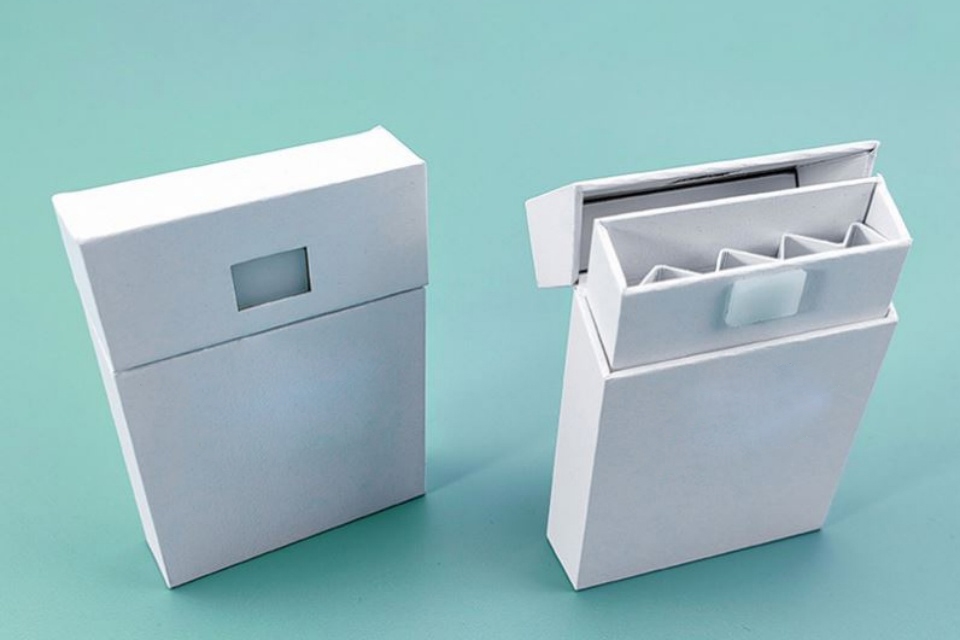

Think of your packaging like LEGO. You have foundational brand elements that never change: your logo treatment, your typography system, your finishing specifications. Then you have variable elements that adapt by product: color fields, strain identifiers, experience descriptors, graphic patterns.

A modular system lets you launch a new strain by simply updating the variable elements, not redesigning the entire box. Your wholesale printer can produce it faster because the structural specifications and core design elements remain consistent. Your printing plates for static elements get reused. Your setup costs drop significantly after the initial system development.

From a brand equity perspective, modularity creates consistency that builds recognition. Customers start recognizing your packaging architecture even before they register your logo. That “oh, that’s a Brand X product” moment happens faster and from farther away when your design system has consistent modular logic.

Building Your Modular System

Start by auditing your current and planned product lines. What varies and what stays constant? Strain names and types change. THC percentages change. Maybe flavor profiles or experiential descriptors change. But your brand story, your quality promises, your logo—those are constants.

Design your box architecture around that reality. Maybe your bottom third is always your brand color field with logo and tagline. Your middle section is a variable color block that codes for strain type. Your top section is clean white space for strain name and compliance information. The proportions and positions stay fixed; the content within them varies.

Work with your designer and printer to establish the system specifications: exact dimensions for variable areas, approved color palette for strain coding, typography rules, finishing specifications. Document everything in a brand packaging guide. This becomes your playbook for launching new products quickly and cost-effectively.

Cost Benefits Across the Product Lifecycle

The ROI on modular systems isn’t immediate—you’ll invest more up-front in system development. But the payback comes with every subsequent product launch. Instead of $3,000 in design fees and multiple revision rounds for each new strain, you’re spending a few hundred dollars on content updates within the established system.

Your wholesale printing costs improve too. Printers give better pricing when they’re producing variations on a familiar structure rather than setting up entirely new jobs. Your quality control becomes easier because you’re checking content variations within a known framework rather than evaluating completely new designs.

Perhaps most valuably, modular systems let you move fast. When you identify a hot new strain or need to respond to market opportunities quickly, you can design, approve, and order new packaging in days instead of weeks. Speed to market has real revenue implications in cannabis where trends and regulations shift rapidly.

Branding Strategies That Extend Beyond the Box

Your wholesale pre-roll boxes don’t exist in isolation. They’re touchpoints in a larger brand experience that includes your website, your social media, your dispensary relationships, and your customer interactions. The most successful brands think holistically about how packaging fits into the complete brand ecosystem.

Creating Packaging That Tells Your Brand Story

Every box is an opportunity to communicate who you are and why you matter. But you can’t tell your entire story on a 3×1 inch panel. You need to choose the most compelling elements and communicate them efficiently. I recommend the “

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory