-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

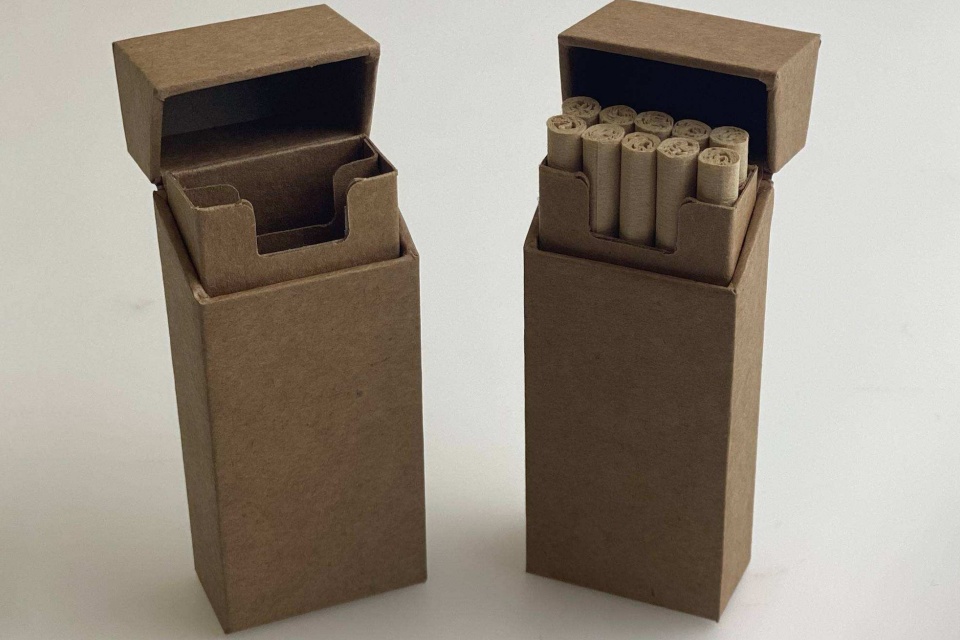

B2B Pre Roll Packaging Boxes OEM

A practical guide to B2B OEM pre-roll packaging boxes—compliance, child-resistant specs, structures, materials, finishes, and supplier checks with Zhibang.

If you sell pre-rolls in bulk, packaging isn’t “just a box.” It’s your compliance file, your shelf presence, and your ops sanity… all smashed into one SKU.

CheapCannabisPackaging.com positions itself as a “Reliable Manufacturer for Cannabis Packaging in China”, doing OEM/ODM, bulk wholesale, and fully custom work across Pre Roll Packaging, Child Resistant Packaging, Paper Tube Packaging, Vape Cartridge Packaging, and Concentrate lines. And it’s backed by Zhibang, which matters when a buyer asks, “who actually makes this?”

Below are the key arguments B2B buyers care about, with real use cases and a couple tables you can reuse in your content.

Table of Contents

Start with sales-market regulations: cannabis packaging compliance comes first

Here’s the blunt truth: you can’t ship what you can’t sell.

For example, Health Canada requires cannabis products to be in a child-resistant container and to include mandatory warning + standardized cannabis symbol (where applicable) + product info like THC/CBD and licence holder details. If you design a pretty box first, then “add compliance later,” you’re just buying rework.

A very real B2B scenario: you launch in one market, then your distributor says, “Cool, now do two more states.” You don’t want a full redesign. You want a stable dieline and swappable warning panels (same structure, new labels). CheapCannabisPackaging.com literally frames this as keeping the dieline and swapping warnings per market.

Compliance documentation checklist for B2B pre roll packaging boxes OEM

| What the buyer checks | What you ask the OEM | What you file for audits |

|---|---|---|

| Child-resistant requirement | Which CR mechanism (press+slide / push-lock / CR tube) and what test method | CR test report aligned to PPPA / 16 CFR 1700.20 (US) |

| Label fields & warnings | Where do strain, THC/CBD, warning panel, tracking go (flat panels vs curves) | Approved artwork + dieline + version control |

| “Looks like candy” risk | Do we avoid cartoon vibe / kid-appeal | Brand guideline + regulator notes (internal) |

| Multi-market scaling | Can we keep the same dieline and only swap market text | Change log per market (SKU discipline) |

Not legal advice, but yeah… this table saves you pain.

Child-resistant packaging definition: PPPA “special packaging” and 16 CFR 1700

In the U.S., people say “CPSC certified” a lot. What matters is the PPPA framework and the 16 CFR Part 1700 testing logic.

CPSC’s business guidance defines “special packaging” as packaging designed to be significantly difficult for children under 5 to open, while not difficult for adults to use properly. And the regulation also gets specific about performance targets and adult usability.

CheapCannabisPackaging.com talks about this in plain terms: clear the legal bar first, then talk colours and logos. It directly calls out PPPA and 16 CFR 1700.20 child-resistant testing in its CR tube guidance.

ASTM D3475: why “CR package type” questions show up in buyer RFQs

Some buyers don’t just want “child resistant.” They want to know what kind.

ASTM D3475 is a classification scheme describing motions/skills/tools needed to open different CR package types. It’s not an endorsement list, but it gives shared language for procurement and compliance teams.

So when a procurement manager asks, “Is this press-and-slide or squeeze-and-pull type?” they’re trying to avoid mystery mechanisms that fail audits or fail on the line.

Don’t source on unit price: total landed cost and delivery certainty

A cheap quote can still be expensive. Not with math on a spreadsheet—more like “hidden chaos”:

- SKU creep: one strain becomes ten, now you need a system

- shade drift: blacks don’t match across batches, your shelf looks messy

- cap mismatch: tubes from one vendor, caps from another… and now nothing closes right

CheapCannabisPackaging.com calls this out in a very real way: mixing suppliers can lead to mismatched parts and even different shades of the same color.

Also, if you run B2B, you care about bulk wholesale + OEM/ODM workflow that doesn’t create drama. Their pre-roll design guide positions exactly that: bulk, OEM/ODM, and full custom across your product lines.

Certifications and test reports: ISO 8317 logic, CR reports, FSC paper sourcing

Buyers don’t want vibes. They want paperwork.

On the CR side, their dispensary best-practices content explicitly mentions CPSC/PPPA style child-resistance and “tested similar to ISO 8317 logic.”

On the sustainability + paper side, their “sustainable supplier” page says serious suppliers should talk about paper sourcing certifications like FSC.

Even if a buyer doesn’t demand these on day one, they will when they scale. That’s just how MSOs and distributors operate.

In-house capability matters: sampling, dieline control, print finishes

B2B buyers will ask: “Can you sample fast, and can you keep the dieline stable?”

CheapCannabisPackaging.com highlights fast sampling / quick prototyping as a factory capability. That’s not fluff. It’s how you avoid burning weeks while your launch window closes.

And for print: you need a supplier who can do the finishes consistently, not “sometimes good, sometimes meh.”

Structure choices: pre roll multipack boxes, CR slider boxes, sleeve boxes, magnetic rigid boxes

Your structure is basically your strategy.

CheapCannabisPackaging.com’s own guidance lists common picks: rigid boxes (magnetic / double-door / hexagon), CR slider/push boxes, plus glass tubes, paper tubes, and mylar-style bags.

Here are concrete examples from their catalog:

- CR slider multipack: described as a “CPSC-certified child-resistant sliding box,” fits five pre-rolls, uses fluted dividers, and leaves big panels for branding/compliance.

- Sleeve multipack: a 7-pack sleeve box with an insert and pull handle; it calls out gold hot foil stamping and matte lamination.

Structure vs scenario matrix (for B2B pre roll packaging boxes OEM)

| Structure keyword | Best-fit scenario | Why buyers like it | Watch-outs |

|---|---|---|---|

| Child Resistant Pre-roll Sliding Box | Dispensary multipack, compliance-heavy shelves | Press+slide behavior, dividers reduce crush, big label space | Make sure CR works after repeated opens |

| Pre Roll Sleeve Box (7-pack) | “Grab-and-go” bundles, value tiers | Fast open, tidy insert, decent billboard area | Sleeve friction + tolerances matter (dont eyeball it) |

| Magnetic rigid box | Tourist traffic, gift sets, limited drops | Premium feel, strong shelf blocking | More parts, more QC checkpoints |

| Custom Child Resistant Pre Roll Tubes | Singles, travel, smell control | PPPA/16 CFR talk is clean; tube protects aroma | Don’t mix tube/cap suppliers (shade + fit issues) |

Materials: rigid paperboard, recycled paperboard, paper tube packaging

Material choice is not a “design mood.” It’s a logistics call.

Our pre-roll guide frames it simply: pick from paper tubes, rigid boxes, and other formats based on freshness and use. Their sustainability page pushes a paper-first direction, calling out recycled board, magnetic multi-packs, and paper tubes as ways to cut plastic.

And yeah, if you export to regions tightening packaging rules, it helps to align with where policy is moving. The EU’s packaging waste regulation direction pushes recyclability and clearer labels (broadly speaking).

Printing and finishing: offset printing, matte lamination, hot foil, debossing

B2B buyers want packaging that looks consistent across pallets, not just in one nice photo.

Our sleeve box example calls out offset printing, gold hot foil stamping, and matte lamination. Their CR slider product page also lists customization like labeling, debossing, sleeves.

That’s how you solve a common pain point: “We need compliance text + brand look, but we don’t want the box to look like a warning label only.”

OEM value: one factory for pre roll packaging, vape cartridge packaging, concentrate containers, paper tubes

This is where Zhibang placement feels natural.

Dispensary and distributor buyers hate vendor sprawl. CheapCannabisPackaging.com spells out the exact headaches: they want one vendor across pre-rolls, vapes, tubes, jars; they need CR certs, dieline tweaks, and stable lead times/MOQs.

It even gives practical talk-tracks like:

- match an existing pack size, upgrade into CR drawer/sleeve

- keep dieline, swap warnings for new markets

- run a paper tube + multipack box with the same color profile

That’s very B2B. That’s how buyers buy.

Sustainability narrative: recycled board, paper-first SKUs, and anti-tamper options

Sustainability only works when it doesn’t break compliance or ops.

Their sustainability page literally says: you don’t need another pretty box; you need packaging that passes CR tests, hits MOQ, and doesn’t trash the planet. (The grammar is rough, but the point is right.)

And if shrink and tampering is a pain, Zhibang content also pushes tamper-evident and serialized cannabis packaging to deter tampering and cut shrink.

Packaging as a communication tool: retail trust, regulator trust, reorder trust

Final argument: in B2B, packaging is a signal.

When your box looks clean, closes right, survives shipping, and carries compliance info without looking like chaos… buyers feel safe reordering. If it feels sloppy, they hesitate. Simple.

So if you’re building a B2B Pre Roll Packaging Boxes OEM program, don’t chase random structures. Build a system: CR where needed, paper tubes where it makes sense, stable dielines, and repeatable printing. Zhibang (through CheapCannabisPackaging.com) positions itself to support that kind of bulk OEM/ODM setup across your full cannabis packaging lineup.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory