-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Impact Of Federal Reclassification Of Cannabis On Packaging

Cannabis may move to Schedule III, so packaging must level up: labels, child-resistant features, better barriers, and vape boxes built for compliance and trust.

Federal cannabis “reclassification” (moving marijuana from Schedule I toward Schedule III) isn’t finished yet, but the process is real. In August 2023, HHS formally recommended Schedule III, and in May 2024, DOJ announced it submitted a proposed rule to start the rulemaking process.

Here’s the practical takeaway: packaging stops being “nice branding” and starts acting like part of your compliance system. That shift hits every box style you sell—especially vape cartridge packaging, where you’re already dealing with leak risk, smell control, and “tiny label, too much info” problems.

Before we jump in, this quick table ties the core arguments to what you actually do on packaging lines.

| Argument (from the article) | What it means in real packaging work | “Do this” checklist (especially for vape carts) | Argument source |

|---|---|---|---|

| Legal standards become the backbone | More pharma-like expectations: labeling control, traceability, safety features | Lock your dieline; reserve warning zones; plan batch codes/serialization; make CR + tamper-evidence standard on key SKUs | Cheap Cannabis Packaging article |

| Barrier & material expectations surge | Materials matter more: shelf life, UV, oxygen, migration risk | Add barrier laminates/UV layers early; don’t “upgrade later”; stress-test for shipping heat | Cheap Cannabis Packaging article |

| Claims & graphics tighten | More scrutiny on medical-ish language and “effect” vibes | Strip risky claims; keep dosing visuals careful; leave space for disclaimers/lab readability | Cheap Cannabis Packaging article |

| Brand trust becomes packaging capital | Trust signals become sales signals | Use clean CR mechanisms; tight tolerances; tamper features that feel solid; consistent print QC | Cheap Cannabis Packaging article |

| Cost, supply chain & margin pressures | Compliance packaging can create SKU chaos + reprint hell | Modular SKUs, fewer dielines, controlled revisions; plan inventory instead of last-minute scramble | Cheap Cannabis Packaging article |

| Strategic moves you can take now | Prepare now, not after the final rule lands | Audit designs vs drug-style labeling; pilot barrier/tamper/UV; choose a vendor who speaks compliance | Cheap Cannabis Packaging article |

Table of Contents

1. Legal Standards Become Backbone, Not Afterthoughts

Right now, cannabis packaging lives in a messy reality: state-by-state rules, plus a lot of “we do what the market expects.” The article calls out what changes under a Schedule III world: DEA/FDA-style expectations could tighten around labeling, safety, and traceability.

Even the official rulemaking docs show the direction: DOJ/DEA started formal steps to consider moving marijuana to Schedule III, with hearings and docket procedures already laid out.

So what does that mean for you?

- Your packaging becomes a compliance stack, not just a marketing wrapper.

- You’ll feel pressure to build in: batch codes, traceability, warning space, and stronger safety features.

- If you wait, you’ll end up in retrofit mode (label redesigns, reprints, new inserts). That’s the worst mode. It’s chaotic and expensive.

Vape cart scenario (very common):

You’ve got a slim box, a small panel, and a retailer that wants “more info.” If regulators also want clearer warnings and traceability, you run out of real estate fast. The fix isn’t “smaller font.” The fix is dielines designed with compliance zones from day one.

Also, don’t ignore child-resistant (CR). If cannabis moves closer to “regulated substance” framing, CR expectations won’t get softer. The PPPA framework defines “special packaging” as something significantly difficult for kids under 5 but usable for adults.

And the testing specs in the federal CR packaging rules are very explicit.

That’s why your CR mechanism choice matters. A “kinda works” closure becomes a liability.

2. Barrier & Material Expectations Surge

If cannabis gets treated more like medicine, product integrity gets more attention. The article puts it plainly: you won’t “add barrier later.” You build it in early.

For vape cartridges, barrier thinking isn’t optional anyway. You already fight:

- terp loss (aroma fades)

- oxidation (taste shifts)

- UV (bad for many formulations)

- shipping stress (heat + vibration)

The article lists likely “baseline” upgrades: barrier films, multi-layer laminates, oxygen scavengers, opaque/UV-shielding layers.

Here’s the non-obvious part: material choices also affect compliance. If regulators start caring more about migration, stability, or consistency, your “good enough” plastic choice can become a question mark. The article even flags plastics potentially getting more scrutiny for quality impact.

Vape cart scenario:

Your brand scales from one state to five. Suddenly you ship farther. Heat exposure rises. Returns start. People blame your oil, but packaging was the weak link.

If you had a vendor push a better barrier spec early, you’d avoid that headache. It happens a lot.

3. Claims, Graphics & Marketing Controls Tighten

This is where brands trip. Not because they’re “bad,” but because they get excited and write stuff that sounds medical.

The article warns that health/therapeutic claims may invite more FDA scrutiny unless they’re backed properly.

It also warns that packaging implying “medical” or “prescription-grade” may trigger disclaimers or drug-label style treatment.

So if you sell vape carts, here’s the safer play:

- Don’t print “clinically proven,” “treats anxiety,” “sleep cure,” etc.

- Be careful with effect graphics that look like dosing instructions.

- Keep your language plain. (Also, consumers trust plain language more than hypey stuff.)

Small grammar truth: your label is not a billboard, it’s a legal document too. That sounds harsh, but it’s real.

4. Brand Trust Becomes Packaging Capital

When rules get tighter, trust becomes more valuable. The article says packaging credibility becomes a differentiator—through CR closures, tamper evidence, serialized liners, and “serious” structure.

I’ll say it in a more street-level way:

When your box feels sturdy, opens right, and looks consistent, buyers assume your oil is consistent too. That’s not always logical, but humans do it.

Vape cart scenario:

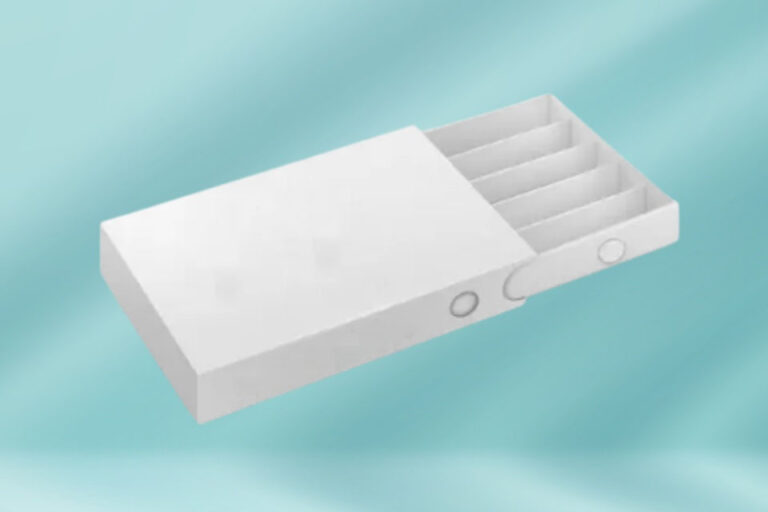

A customer compares two carts. One comes in a thin tuck box with sloppy glue and blurry print. The other comes in a clean drawer box with a CR feature and a firm insert that holds the cart tight.

Even before they try the product, they already “picked” a winner.

If you sell wholesale, this matters even more. Retailers hate returns. They’ll push brands toward packaging that reduces drama.

5. Cost, Supply Chain & Margin Pressures

The article calls out the pressure plainly: stricter materials, tighter tolerances, and compliance steps increase load on your packaging program.

But the bigger killer isn’t material cost. It’s operational mess:

- too many SKUs (SKU sprawl)

- too many dielines

- uncontrolled label revisions

- last-minute compliance edits (aka: reprint hell)

The article suggests evolving strategies like batch runs, modular SKUs, forward inventory, responsive design.

That’s solid advice. And it’s very “manufacturer brain,” which is good.

6. Strategic Moves You Can Take Right Now

The article gives a direct checklist: audit designs, pilot upgraded laminates/serialization/tamper/UV, build dielines with disclaimer and lab-readability zones, and partner early with vendors who understand medicine-level compliance.

Here’s how that maps to your site and what you sell.

Our positioning is already aligned with this direction:

- We’re a direct manufacturer in China (“Reliable Manufacturer for Cannabis Packaging in China”).

- We highlight full design support and rapid sampling.

- We sell the exact categories brands will lean on as rules tighten: Child Resistant Packaging, Concentrate Container Packaging, Paper Tube Packaging, Pre Roll Packaging, Vape Cartridge Packaging.

- Our vape category messaging focuses on secure, customizable packaging that protects freshness—that’s the right language for this moment.

What I’d do if you’re selling vape cartridge packaging tomorrow morning:

- Offer “reg-ready” dielines: pre-built zones for warnings, batch/date, lab info.

- Push a small set of proven structures (drawer boxes + inserts) to reduce SKU chaos.

- Make CR/tamper options easy to choose, not a custom science project.

- Build a simple “artwork rules” sheet: what not to claim, what space you must keep.

- Talk like a partner, not a printer: “We’ll help you avoid compliance rework.”

And yes—this is where it’s natural to mention Zhibang. If Zhibang supports OEM/ODM, bulk wholesale, and consistent QC workflows, you position it as the team that helps brands move from “cool box” to “compliance + shelf appeal” without losing speed. (You don’t need to say it fancy. Just say it straight.)

Closing Reflections

The article’s final point lands: reclassification won’t be overnight, but packaging becomes a “contract” with the buyer—safety, seriousness, intent.

And the government docs show the process isn’t theoretical: HHS made a formal recommendation (Aug 29, 2023), DOJ submitted a proposed rule (May 16, 2024), and DEA published rulemaking steps and hearing notices in the Federal Register.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory