-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Best Practices For Custom Paper Tube Packaging That Meet Child-Resistant Standards

Guide to child-resistant paper tube packaging: key standards, smart structures, and OEM/ODM tips for safer, compliant cannabis and pre-roll brands.

Below is a practical guide to best practices for custom paper tube packaging that really meet child-resistant standards, with real keywords, real use cases, and a bit of factory-side black talk from Zhibang behind Cheap Cannabis Packaging in China.

Table of Contents

Why Child-Resistant Paper Tube Packaging Matters For Cannabis Brands

For cannabis, pre-rolls, vapes, and even infused flower, child-resistant paper tube packaging is now baseline, not upgrade. Many markets require you to meet CPSC 16 CFR 1700.20 in North America or ISO 8317 / EN 862 in Europe. These rules say, in short:

- Most small kids (around 42–51 months) must not be able to open the pack in a timed test.

- Most adults (often 50–70 years) must be able to open it within the test window.

So your cute twist tube for a pre-roll? If a panel of children can crack it in five minutes, it’s a fail, no matter how nice the print or emboss is.

For you as a buyer, the job is simple on paper:

“I need a CR paper tube that passes 16 CFR 1700.20 and is still easy for customers to open.”

The hard part is everything behind that sentence: structure, materials, testing, artwork, MOQ, and change control.

Design Child-Resistant Paper Tubes Backwards From 16 CFR 1700.20 and ISO 8317

CPSC 16 CFR 1700.20 Child-Resistant Testing Basics

A real CR paper tube must be able to pass a panel test roughly like this:

- Child panel: 5-year-old and under children try to open the package. At least about 85% of them fail to get inside within the test time.

- Adult panel: adults 50–70 are asked to open and reclose. Around 90% have to succeed within the time window.

So when you talk to a supplier, don’t just say “make it childproof”. You want to hear words like:

- “This structure already passed 16 CFR 1700.20 panel test.”

- “We have lab reports, you can tie them to your SKU.”

- “If we change the height or inner diameter, we check if retest is needed.”

If your vendor cant explain the test flow in simple words, that’s a red flag.

ISO 8317 and EN 862 Requirements For Reclosable CR Packaging

For EU markets, the keyword you’ll see is “ISO 8317 child-resistant packaging” for reclosable packs and EN 862 for non-reclosable ones. They follow a similar logic: kids must struggle, adults must manage.

If you sell in multi-region, the safe route is:

- Ask for structures that already have ISO 8317-type certificates.

- Keep all test reports on file – auditors love paperwork.

- Make sure your brand edits (height, artwork, liner) don’t silently break that compliance.

Structural Best Practices For CR Paper Tubes (Twist, Press, Pull)

Two-Step Child-Resistant Closures On Paper Tube Packaging

Most successful CR paper tube packaging uses a two-step motion. Single friction fit is almost never enough. Common structures we see at Zhibang:

- Twist-to-unlock paper tubes

Inner and outer tube have a locking groove. You twist to align, then pull. For kids, that “twist + pull” logic is surprisingly hard. - Press-button child-resistant paper tubes

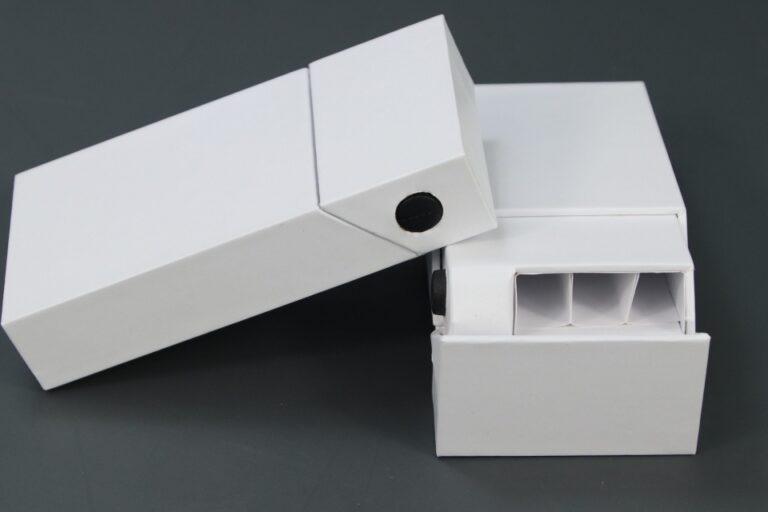

There’s a hidden or visible button on the side of the cardboard cylinder. Adults press the button while pulling the lid. This kind of structure are tricky for children, but feels natural for regular consumers. - Push-and-slide formats

Mostly for slim vape pen tubes – you push from one end and slide the inner tray out, but only after a locking notch is released.

The pattern: two deliberate actions, not one random tug. When you discuss a new dieline, always ask:

“What is the adult opening story? What is the kid confusion story?”

If your supplier can paint both pictures clearly, you’re on the right track.

Senior-Friendly Opening Force and Panel Test Results

Regulators don’t want kids in your product, but they also don’t want grandma with arthritis stuck with a sealed tube forever.

So good CR paper tubes must:

- Use ergonomic grip zones instead of tiny tabs.

- Keep opening force high enough for kids, but not so crazy that adults need tools.

- Provide simple graphics (“PRESS”, arrows, twist icons) right next to the closure.

When we prototype at Zhibang, we’ll often send you two or three tightening levels so you can test with your own team – sometimes your budtenders become the unofficial “adult panel”.

Materials, Inserts, and Barrier Layers In Cannabis Paper Tube Packaging

FSC Paperboard, Inner Liners, and Recyclable CR Paper Tubes

Cannabis brands care about eco story and product protection at the same time. On the material side, best practice looks like:

- Outer tube: FSC-certified paperboard, often kraft or white, with enough thickness to support the CR lock without deforming.

- Inner liner: optional PE coating, aluminum foil, or glassine to handle moisture, aroma, and oil.

- Insert: foam, molded paper, or paperboard collar to hold the pre-roll, vape cartridge, or flower jar steady.

In cannabis, we see a lot of pre-roll paper tubes and vape cartridge paper tubes where a simple white insert locks the cartridge in place and adds that extra resistance when you pull.

The trick is to keep the whole structure still recyclable in many markets. That means:

- Avoid too many plastic bits.

- Use glues and films that don’t kill recyclability.

- Keep your ESG slide deck honest when investors ask about packaging.

Graphics, Tamper-Evident Features, and Warning Icons On CR Paper Tubes

A CR tube that looks like a toy is asking for trouble. Best practice is to combine:

- Tamper-evident (TE) features: tear strip, perforated label, or a seal that clearly shows “first opening”.

- Warning icons: THC symbol, age restriction, hazard icon where required.

- Clear opening instructions: “Press & turn”, arrows, small pictogram of the hand.

On the design side, your artwork team should get a dieline with reserved zones:

- One area for brand wow (logo, color, strain name).

- One area for compliance (warnings, QR, batch).

- One area around the closure that is kept clean so users can actually see how to open.

At Cheap Cannabis Packaging we usually do a quick “artwork pass” for new clients: check your file for missing warnings, overlapping text, or key text placed right over a button.

Lab-Certified Child-Resistant Paper Tube Packaging and Change Control

Using Third-Party Labs, Panel Tests, and ISO 13127

The sentence you want to see on your spec sheet is simple:

“Structure: lab-certified child-resistant paper tube, tested under 16 CFR 1700.20 / ISO 8317, report on file.”

Third-party lab certification is the only way to claim real CR performance. Labs run the child panel, adult panel, and issue a report.

Once you pick a certified structure, lock in a few rules:

- Any big change (height, diameter, wall thickness, locking geometry) should trigger a retest or at least mechanical test under ISO 13127.

- Any minor change (artwork only, simple color change) still needs internal review and a written “no-retest” decision.

- Keep all reports bundled with your spec and PO history.

You dont want to explain to a state inspector why your “new version” of the tube doesn’t match the old lab report.

Practical Use Cases: Pre-Roll, Vape Cartridge, and Flower Paper Tube Packaging

On the Cheap Cannabis Packaging “Paper Tube Packaging” page, you’ll see exactly the kind of use cases most brands need:

- CR paper tubes for vape cartridges

Slim, long cylinders with a white insert or cardboard collar to hold a 1 ml cart. The closure is often twist or push-and-lock, so the cart doesn’t rattle or crack during shipping. - Child-resistant pre-roll paper tubes

Cardboard cylindrical boxes for singles or multi-packs, with stronger walls and sometimes an odor-control liner to keep aroma inside the tube, not across the whole dispensary shelf. - Cannabis flower paper tubes

Wider tubes for small jars or pouches, used as a premium outer pack. These focus on shelf impact and brand storytelling, while still using a CR closure on the tube or the inner container.

In each scenario, MOQ, lead time, and filling line are different. When we talk with wholesalers, the questions sound like:

- “Can this structure run on my existing filling line or everything hand-pack?”

- “Can you keep the same CR rating if we change from 109 mm to 116 mm height?”

- “What’s the realistic lead time if I do two SKUs, one for THC and one for CBD only?”

If your supplier can’t run this conversation, you’re basically testing in production, and that’s too expensive.

Summary Table: Best Practices For Custom CR Paper Tube Packaging

You can drop this table straight into your internal spec doc:

| # | Best Practice For CR Paper Tubes | What It Means In Real Life |

|---|---|---|

| 1 | Design from 16 CFR 1700.20 / ISO 8317 backwards | Pick a structure that already passed CR tests; let standards define your locking system, not the other way around. |

| 2 | Use two-step closures | Twist-then-pull, press-then-pull, or push-then-slide instead of simple friction caps. |

| 3 | Check senior-friendly opening | Make sure a 60-year-old can open and reclose without tools, but kids still fail in panel tests. |

| 4 | Combine FSC board + functional liner | Enough thickness to support the lock, plus liner or inner wrap for aroma, moisture, and oil resistance. |

| 5 | Add inserts / collars | Keep pre-rolls, carts, or flower jars from moving; at the same time add a bit of controlled resistance. |

| 6 | Reserve space for TE & warnings | Tear strip, seal label, and clear icons around the opening – no clutter over the closure. |

| 7 | Use lab-certified structures | Third-party report under 16 CFR 1700.20 / ISO 8317 on file; never rely only on “we tested in-house”. |

| 8 | Apply change control | Any change in locking geometry or material triggers a check; big changes may need new lab test. |

| 9 | Align branding + compliance | Plan dieline so brand graphics, strain names, and legal info all live happily on one tube. |

| 10 | Fit your MOQ and filling process | Choose a CR tube that works with your packing line, your volume, and your warehouse reality. |

How Zhibang (Cheap Cannabis Packaging) Supports OEM/ODM Child-Resistant Paper Tubes

Zhibang, the factory behind Cheap Cannabis Packaging, positions itself as a reliable manufacturer for cannabis packaging in China, with an offer focused on:

- Child resistant packaging,

- Concentrate container packaging,

- Paper tube packaging,

- Pre roll packaging,

- Vape cartridge packaging,

all in OEM/ODM, bulk wholesale, and custom projects.

For paper tubes specifically, the value is:

- Ready-to-use CR paper tube structures that already follow child-resistant standards.

- Support on dieline, artwork, and compliance layout, so your design team doesn’t guess.

- Flexible MOQ and bulk pricing for distributors and brand houses.

- Transparent lead time and stable quality once you drop a PO.

If you treat your custom paper tube as a serious CR component, not just a cute cylinder, you protect kids, make regulators happy, and still keep your brand looking sharp on shelf. And with the right partner on the factory side, you don’t need to re-learn 16 CFR 1700.20 from scratch every new SKU.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory