-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Child Resistant Vape Packaging Suppliers

Quick guide to child-resistant vape packaging: vet suppliers, meet PPPA/ISO 8317/TPD, choose CR boxes, and leverage OEM/ODM with Cheap Cannabis Packaging.

You don’t want recalls, platform takedowns, or angry parents on the news. So let’s talk child resistant vape packaging suppliers in plain English—how to vet them, what to ask, and how this ties back to Vape Cartridge Packaging you actually use day-to-day.

Table of Contents

PPPA 16 CFR 1700.20 testing — why it’s your ticket in

If you sell nicotine e-liquid or vape hardware in the U.S., PPPA (Poison Prevention Packaging Act) and 16 CFR 1700.20 testing isn’t optional. It’s entry pass. The test checks two things at once:

- Child-resistant: kids under 5 can’t open it during the panel test.

- Senior-friendly: older adults can still open it without swearing.

Ask a supplier for: full test report (not just a logo), sample ID, test dates, method, pass/fail by panel, and lab accreditation. No paper? No deal.

ISO 8317 child-resistant closures for e-liquid bottles

Outside the U.S., or for cross-border shipments, ISO 8317 (reclosable packages) is the common badge. For bottles that means CRC caps + inserts + tamper band. Look for language like “press-and-turn”, “push-down-and-twist”, “child-proof dropper” (the slang isn’t perfect, but you get it). Pro tip: check torque spec. If cap torque is all over the place, leaks happen, panels fail, you cry.

EU TPD no-leak refill mechanism & tamper-evident seals

Doing EU/UK? TPD expects child-resistant, tamper-evident, and no-leak refill. That impacts tips, gaskets, needle-nose adapters, even orifice size. Tell suppliers your juice system: VG/PG ratio, flavor solvents, and nicotine salt or not. Materials must play nice: HDPE/PET bottle + PP cap is common; seals often LDPE/TPU. Ask for compatibility statements not just marketing words.

Senior-friendly usability vs child resistance

CR ≠ impossible to open. The standard literally says both: tough for kids, OK for adults. If your customers complain “cap too stiff,” you’ll get churn. Request senior-friendly results, opening force curves, and ergonomic notes. And yes, quick line trials help: five-minute pilot on your filling line to see if caps cross-thread, bands snap, hands get tired. Boring? maybe. But saves returns.

Vape Cartridge Packaging — supplier checklist (OEM/ODM, bulk, private label)

We focus here because your site category is Vape Cartridge Packaging. At Cheap Cannabis Packaging, we manufacture and source Child Resistant Packaging, Concentrate Container Packaging, Paper Tube Packaging, Pre Roll Packaging, Vape Cartridge Packaging with custom/OEM/ODM for wholesalers and brands. Short version: we understand the messy bits—MOQs, lead time, color match, line fit, AQL.

What to ask

| Keyword / Spec | What to verify with supplier | Why it matters |

|---|---|---|

| 16 CFR 1700.20 / PPPA | Full test report, lab accreditations, panel data | U.S. compliance baseline; platforms look for it |

| ISO 8317 (reclosable) | Certificate + report (cap + bottle as a set) | Global e-liquid acceptance; smoother customs |

| TPD no-leak refill | Tip design, gasket, no-spill demo, TE band proof | Stops leakage claims; required in EU/UK |

| Senior-friendly | Data on opening torque, usability notes | Real customers can open it; fewer returns |

| Material + chem compat | HDPE/PET/PP resin grades; food-contact statements | Nicotine, flavors, terpenes won’t eat seals |

| Tamper-evident (TE) | Band integrity, break force spec | Visible safety; less shrink & swap |

| AQL / QC plan | Incoming/inline/outgoing checks; caps torque window | Fewer leakers; better line OEE |

| Batch traceability | Lot code on caps/bottles; retain samples | Recall ready (hope you never need it) |

| Secondary CR box | Slide-lock/push-pin structure with CR report | Carts need CR outer packs too |

| Customization | Color, finish, deboss/UV, sticker space | Brand pop without killing lead time |

Real-world scenarios (and the fix)

- “We switched flavor house, now caps leak.”

Some flavor solvents soften gaskets. Fix: request compatibility + swell test with your new concentrate. Swap insert polymer if needed. - “Store says seniors can’t open it.”

Increase knurl depth on cap, tweak torque range, or move to press-and-turn with better grip. Test with a small senior panel. Yes, small data still helps. - “Custom color looks off under shop light.”

Share Pantone + lighting spec (D65 vs store LED). Ask for metamerism check. Saves repaints. - “Outer box passes vibe, fails child-resistant.”

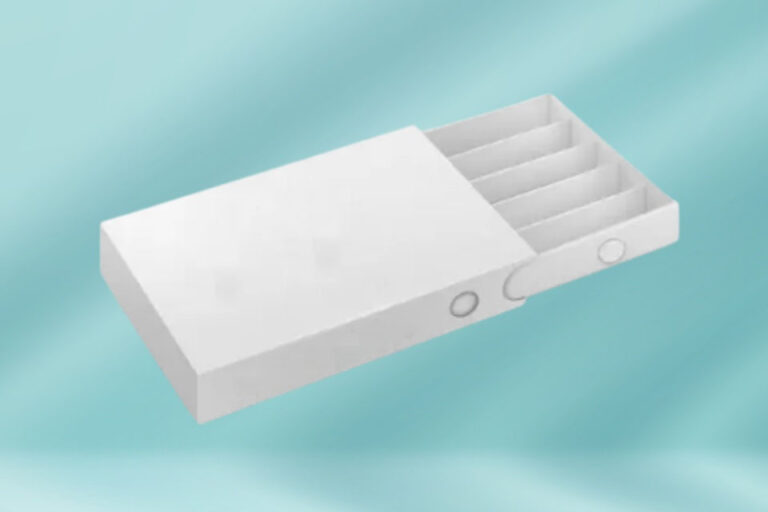

Pretty drawer box ≠ CR. Add push-pin or squeeze-release with certified structure. Ask for the CR report on that die-line, not “similar box.” See push-pin options for reference mechanics.

Supplier scorecard — quick way to compare vendors

| Criterion | Weight | Pass notes |

|---|---|---|

| Compliance docs in 24–48h | 25% | Full reports, no redactions |

| Cap torque consistency (CpK) | 15% | Narrow window, fewer leaks |

| Senior-friendly open rate | 10% | Clear test method, data-based |

| TE band break rate | 10% | Clean break, no shrapnel |

| TPD no-leak refill proof | 10% | Video + report preferred |

| Material & flavor compat | 10% | Statements + sample run |

| AQL & traceability | 10% | Lot codes, retain samples |

| Customization & lead time | 10% | Realistic, honest ETAs |

(Weights are guidance, not math gospel.)

Keyword: child resistant vape packaging suppliers — when to push back

Sometimes you gotta say “no”. If a vendor says:

- “We have logo only, report private.” — Hard pass.

- “Box is CR by design, no test.” — Test or skip.

- “Any cap fits any bottle.” — Not safely. Use matched sets.

- “Senior-friendly optional.” — It’s not; it’s literally in the standard.

Keyword: vape cartridge packaging — carton + insert options that actually work

You’ve got 0.5 mL / 1.0 mL carts, maybe 2-pack or 5-pack displays. Here’s what moves on the shelf and stays compliant:

- CR slide drawer with push-pin: one-hand looks cool, two-step opens.

- Squeeze-release tuck box: slim, stash-friendly, still two actions.

- Paper tube with CR lid: premium feel, travel-safe.

- Blister + CR shell: rugged for courier abuse; tamper-evident clear.

At Cheap Cannabis Packaging, we build these with OEM/ODM options: custom size, foam inserts or molded pulp, UV spot, soft-touch, and batch-print lot code on flaps. Bulk buys get better pricing tiers, not gonna lie. But no silly minimums you can’t hit.

Keyword: ISO 8317 child-resistant closures — bottle + cap as a system

Treat CRC like a system: bottle finish + insert + cap + TE band + torque. Change one, re-check all. For e-liquid fill lines, we set:

- Target torque window (example: mid-range to balance leak vs openability)

- Drop test from typical courier heights

- Thermal cycle (warehouse to van to shelf)

- Shelf-life seal check at 30, 60, 90 days

Small pilot beats big headache.

Keyword: PPPA 16 CFR 1700.15/.20 testing — documents you keep

Keep a compliance pack per SKU:

- Test reports (PPPA / ISO 8317 / EN 862 where applicable)

- Material statements (HDPE/PET/PP grades, food-contact status)

- Torque spec & line setup sheet

- TE band inspection spec

- AQL records, non-conformance log

- Lot map for traceability

Audits become easy. Marketplace checks too.

Keyword: child resistant packaging for cannabis — value, not just boxes

This is the business bit. CR packaging isn’t only about not failing a test. It impacts:

- Sell-through: clean open, no spills, better reviews.

- Operational cost: stable torque = faster capping, fewer reworks.

- Brand trust: visible TE, consistent color, neat die-lines.

- Regulatory headroom: ready docs make expansion faster.

At Cheap Cannabis Packaging, we manufacture Child Resistant Packaging, Concentrate Container Packaging, Paper Tube Packaging, Pre Roll Packaging, Vape Cartridge Packaging with custom print, sizes, and finishes. Bulk wholesale, OEM/ODM, private label—that’s our lane. We set up line trials, share AQL plans, and keep retain samples. If you need a weird insert for a chunky cart? we model it and cut a pilot. Fast.

Wrap-up: the short checklist you actually use

- Ask for PPPA 16 CFR 1700.20 or ISO 8317 full reports (bottle+cap set / box structure).

- Verify senior-friendly data, not just “it’s easy.”

- Confirm TPD no-leak and tamper-evident if EU/UK.

- Demand material compatibility with your juice/terpenes.

- Lock torque window and do a mini line trial.

- Nail AQL, lot codes, retain samples.

- For Vape Cartridge Packaging, pick a certified CR outer that fits inserts clean, prints crisp, and opens in two steps—see a vape cartridge packaging box or compliant child-resistant vaporizer cartridge packaging for structure references.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory