You need boxes that do more than “look nice.” They’ve gotta pass CR checks, ship safe, stack clean on shelf, and still feel on-brand. That’s where Custom Vape Cartridge Boxes OEM work best. Below is a straight-talk, flexible essay that pulls real shop-floor needs into one place—materials, structures, compliance, and the usual pain points (MOQ, lead time, labeling, SKU creep).

Table of Contents

Vape Cartridge Packaging OEM: What It Actually Solves

OEM means we build around your cartridge size, your hardware (510 thread, PnP, proprietary), and your route to market (dispensary shelf, DTC, distributor master case). With Cheap Cannabis Packaging, you get Vape Cartridge Packaging that nails:

- Fit & Lock: snug inner tray (EVA, paper pulp, foam-free paperboard) so carts don’t rattle.

- Brand panel space: room for strain, potency, batch/lot, QR, and warning blocks.

- Real CR options: push-and-slide sleeves, press-tabs, tear-strips, certified closures.

- Shipping safety: E-flute or rigid board that survives a rough 3PL week.

Child-Resistant Vape Cartridge Packaging (CR)

You already know the drill: child-resistant is baseline in most markets. For vape boxes, common CR tactics are:

- Press-lock sleeves (push here + slide).

- Hidden tab releases that adults open quick, kids… not so much.

- Tamper-evident labels or tear-lines to show it wasn’t opened.

Tip: Pick CR early. CR affects dielines, tray depth, even varnish (some coatings get slippery and fail user tests). Cheap Cannabis Packaging can share house dielines, then tweak to your cart size and brand vibe. If you want a fast reference, check a typical child-resistant vape cartridge box spec and adapt the mechanism to your SKU.

Tamper-Evident Vape Packaging

You want a clear “first-open” moment. Two simple routes:

- Perforated tear strip on the sleeve.

- Label bridge over the opening edge (void if peeled).

Both play nice with batch labeling, and help stores trust what they receive. Also looks clean on unboxing videos (yeah, that matters).

Custom Vape Cartridge Boxes OEM: Structures That Move the Needle

Different channels = different box structures. Here are four that work:

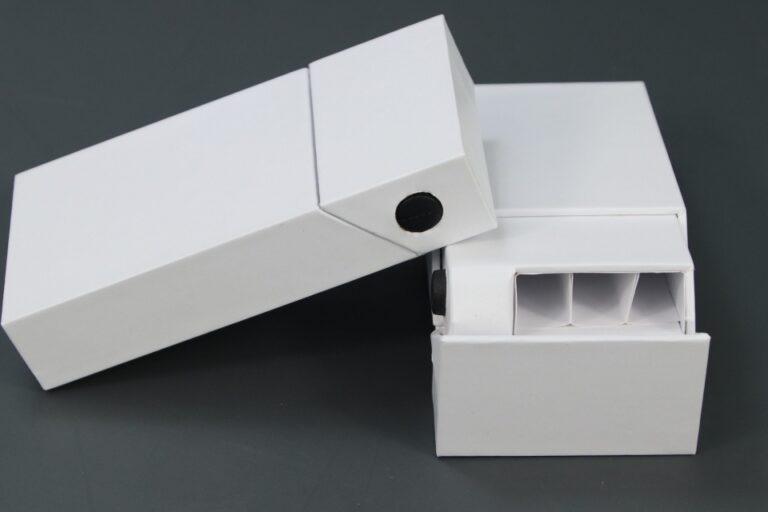

- Drawer box (slide-out): premium feel, good for limited strains.

- Window carton: lets buyers see color & fill without opening; great for quick shelf scan.

- Front-lock crash carton + inner tray: cost-effective, fast to load.

- Counter display shipper: outer case that pops into a display at POS—zero extra displays needed.

Loading flow matters. If your line staff fights the box, your COGS creeps. Ask for “one-hand load” tray cuts and carton angles that match your filling jig.

OEM MOQ and Sampling for Vape Cartridge Packaging

Real talk: you need samples to test fit, check CR action, and run your label printer. With OEM, typical flow:

- White mock for structure fit.

- Printed pre-prod for colors + coatings.

- Production after sign-off, then final QC and ship.

MOQ is friendly for most SKUs (no exact numbers here), and batch buys drop unit cost. We won’t print numbers—just know the economics get better as you scale or consolidate SKUs.

Sustainable Vape Packaging Materials (That Still Protect)

You can go eco without babying the boxes:

- Recycled kraft tubes or uncoated board for that matte, earthy look.

- Molded fiber tray (paper pulp) instead of foam.

- Aqueous coating instead of plastic lamination when possible.

Balance is key: carts are glass/metal; they need real protection in transit. We’ll spec board caliper and tray depth so it doesn’t crush in a master case.

Labeling, Batch, and Dispensary Reality

On the ground, compliance isn’t just a rulebook—it’s operations:

- Big enough warning panels so you don’t reprint stickers last minute.

- UPC + batch + date space designed into the art, not squeezed later.

- No cartoonish graphics where it’s restricted. Keep it adult, readable, clear.

Also, leave label “quiet zones” (blank areas) for markets that add extra stickers at the store level. Saves rework.

Shelf Impact: Window vs. Solid Panel

- Windowed boxes: instant read on cartridge finish and oil color; boosts “what you see is what you get.”

- Solid panels: more room for brand blocks, emboss/deboss, foil accents, spot UV for texture.

Both can sit in counter display shippers so budtenders aren’t hunting for a place to put you. Faster sell-through, cleaner facings.

Paper Tube Packaging for Carts (When It Fits the Brand)

Paper tubes are light, premium, and compact. Add an EVA puck or paper pulp insert to hold the cart vertical. Works if you’re going for a “minimalist craft” identity. We build tubes alongside cartons, so your brand system stays consistent across Pre Roll Packaging, Concentrate Container Packaging, and Vape Cartridge Packaging.

Finishes That Don’t Kill Readability

Sure, you can go loud, but keep text contrast strong:

- Soft-touch feels nice but attracts fingerprints—test it.

- Spot UV on logos/strain blocks gives pop.

- Foil for brand marks; don’t foil the warnings (readability first).

- For a premium open, consider a rigid magnetic-closure vape cartridge box—smooth feel, still label-friendly.

Table: OEM Vape Cartridge Packaging — Quick Spec Cheatsheet

| Topic | What To Decide | Typical Options | Why It Matters |

|---|---|---|---|

| Form Factor | Sleeve, drawer, crash-lock, tube | Drawer / Sleeve / Window carton / Tube | Drives CR method, loading speed, shelf style |

| Child-Resistant | Mechanism type | Press-and-slide, tab-lock, certified closure | Required in many regions; plan dieline early |

| Tamper-Evident | First-open signal | Perforation, label bridge, tear strip | Trust for retailers & consumers |

| Insert/Tray | Hold the cart steady | EVA, paper pulp, paperboard cradle | Anti-rattle, protects glass tank |

| Board Caliper | Stiffness & crush-resistance | Higher gsm SBS/Kraft/Rigid | Survives 3PL; less returns |

| Coatings | Look + handling | Aqueous, matte, soft-touch, spot UV | Tactile feel vs. smudge risk |

| Windows | Show-through or not | PET window, die-cut window | Visual proof, faster shop decisions |

| Label Zones | Compliance & ops | UPC, batch, warnings, QR | Avoid last-minute re-stickering |

| Sustainability | Material & finish | Recycled board, aqueous coat, pulp tray | ESG stories without babying packaging |

| Brand System | Cross-category fit | Match Pre Roll / Concentrate / Tubes | Unified shelf, easier reorders |

| MOQ & Samples | Ramp plan | White mock → pre-prod → mass | Catch problems early, save reprints |

Real-World Use Cases

- Distributor pack-outs: We design the inner pack so 10-count master cases drop into a counter display—no extra kitting. Time saved, errors down.

- Multi-state labeling: Same print run, different label panels. You swap stickers by state; we keep dielines identical.

- Limited drops: Short color runs using the same tooling, just swap plate set. Keeps cost in line, speed up.

- E-com buffer: Slightly thicker board for courier-heavy routes; reduces “crushed corners” tickets.

Why Cheap Cannabis Packaging (and how we help)

We’re a Reliable Manufacturer for Cannabis Packaging in China serving Child Resistant Packaging, Vape Cartridge Packaging, Pre Roll Packaging, Paper Tube Packaging, and Concentrate Container Packaging. OEM/ODM is daily work for us:

- Dieline help so your designer isn’t guessing.

- Trial build to test CR action and tray grip.

- Batch scaling when a SKU suddenly pops.

- QC photos and videos before we ship, so there’s no surprises.

- Bulk orders & wholesale to keep unit cost realistic—no numbers here, but you’ll feel it.

- Need special tweaks? Hit our customization page and we’ll get your brief sorted.

We also know the industry black talk: CR claims, PPPA vibes, shelf facings, case-pack logic, WIP caps, labeler bottlenecks, 3PL drop damage, and the great “cart wobbles” problem. We engineer boxes to kill those issues early.

Vape Cartridge Packaging — Keyword Notes You Can Reuse

Custom Vape Cartridge Boxes OEM

Use when you talk about tailored structures, brand panels, and CR mechanisms.

Child-Resistant Vape Cartridge Packaging

Good for compliance-first sections and CR mechanism choices.

Tamper-Evident Vape Packaging

Great for first-open signals, shipping security, and shelf trust.

Sustainable Vape Packaging Materials

Use for recycled board, aqueous coats, and molded fiber trays.

OEM MOQ and Sampling

Covers white mocks, pre-prod prints, and production sign-off.

Quick FAQ-ish

Q: Will CR slow down loading?

Not if we choose the right mechanism. We tune the opening force and tab size so packers don’t fight it.

Q: Window or no window?

If your oil color is a selling point, window wins. If your brand story is loud, solid panel gives you more print area.

Q: Foam vs. paper tray?

Foam grips best, paper pulp is greener. We can spec a tight paperboard cradle too. Try both in samples.

Q: Can we standardize across SKUs?

Yes. One master dieline, multiple artworks. Keeps your ops simple and reorder fast.