-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Lifecycle Analysis Of Vape Cartridge Packaging Systems

Practical look at vape cartridge packaging lifecycle, from materials to end-of-life, with real-world CRC box design and sourcing tips from Zhibang.

If you run carts, you already know: the little box around a 1 ml cart is doing a lot of heavy lifting. It has to pass child-resistant tests, keep oil safe, stay compliant, look good on a crowded shelf, and still land at a decent landed cost.

Lifecycle analysis (LCA) just puts numbers and logic behind that gut feeling. It asks: from raw paper and plastic to landfill or recycling, where does vape cartridge packaging really hit the planet and your P&L?

Below we walk through that, and also how a factory like Zhibang (Cheap Cannabis Packaging in China) can actually tweak each stage for you.

Table of Contents

Lifecycle Analysis and Environmental Impact of Vape Cartridge Packaging

Vape Cartridge Packaging Lifecycle Stages: From Raw Materials to Disposal

An LCA breaks your vape cartridge packaging into a few big stages:

- Raw materials – paperboard, rigid chipboard, inks, EVA foam, maybe magnets or plastic trays.

- Manufacturing & printing – die-cutting, gluing, child-lock structures, full-color CMYK or Pantone runs.

- Transport & storage – pallets from China to your distro or grow, then to stores.

- Use & display – time on the shelf, unboxing, consumer handling.

- End-of-life – landfill, incineration, maybe recycling, sometimes just litter.

A big UK study on disposable vapes found around 57% of the total greenhouse gas emissions come from raw material extraction and about 26% from manufacturing. Only a small slice comes from final waste treatment.

Your own vape cartridge boxes sit in the same world: most of the impact comes before the box ever hits your warehouse. That means smart design and material choice punch way harder than just hoping customers recycle.

Table 1 – Vape cartridge packaging lifecycle and what you can tweak

| Lifecycle Stage | Typical Situation for Vape Cartridge Packaging | Main Impact Signal (approx) | What a supplier like Zhibang can adjust |

|---|---|---|---|

| Raw materials | Rigid paper drawer box, EVA foam, sometimes magnet, heavy board | Major share of CO₂ and resource use (similar to ~60%+ in vape products overall) | Switch to lighter board, more recycled paper, rethink foam, avoid magnets when not needed |

| Manufacturing & printing | Complex die-cuts, multi-piece child lock, full-coverage print, spot UV everywhere | Energy use, ink consumption, some scrap | Optimize die-line, cut one extra layer, use water-based coating, tighten color coverage |

| Transport | Shipping air (oversized boxes, low packed density) | Extra fuel per unit, higher freight bill | Design slimmer drawer boxes, higher case pack count, better nesting |

| Use & retail | One box per 0.5–1 g cart, sometimes huge for tiny hardware | High “packaging / product” ratio | Move more SKUs to leaner child-resistant sliders or paper tube options |

| End-of-life | Mostly mixed paper + plastic + sometimes magnets, low real recycling rate | Landfill, incineration, long-term micro-waste | Push single-material structures, clear paper recycle stream, minimum plastics |

This is why “Lifecycle Analysis Of Vape Cartridge Packaging Systems” is not just an academic title. It’s literally your margin + compliance + brand story on one spreadsheet.

Child Resistant Vape Cartridge Packaging and Compliance in the Lifecycle

Child Resistant Paper Drawer Box for Cannabis Oil Packaging in LCA View

Look at your Child Resistant Paper Drawer Box for Cannabis Oil Packaging or those button-lock slide-out boxes. They’re doing a lot:

- Child lock cutout or button

- Outer sleeve + inner tray

- Foam or paper insert to hold a 510 cart

- Full-bleed art, strain info, compliance copy

In LCA language, that means: more parts, more steps, more material streams. But you still need CRC to hit local rules. There is no world where you just strip safety out.

So the trick is not “less protection”, but smarter structure:

- Use single-material locking (paper-only child-resistant slider instead of plastic clip).

- Replace thick plastic trays with EVA or paperboard inserts cut for the cart.

- Keep board caliper only as thick as needed for strength and lock performance, not just “feels premium, bro”.

Labs only test function, not weight. If a child-resistant drawer box from Zhibang still passes the push-and-pull protocol but uses one less layer of board, that helps both your LCA score and your freight invoice.

In real life, you tell your vendor:

“We need CRC, but we don’t wanna ship bricks. Show me a slim lock drawer for 1 g cart, 4-color outside, no magnet, clean inside.”

A factory that actually understands lifecycle and compliance at the same time can come back with a lean die-line instead of just adding stuff on.

Custom Printed Vape Cartridge Boxes, Branding, and Carbon Footprint

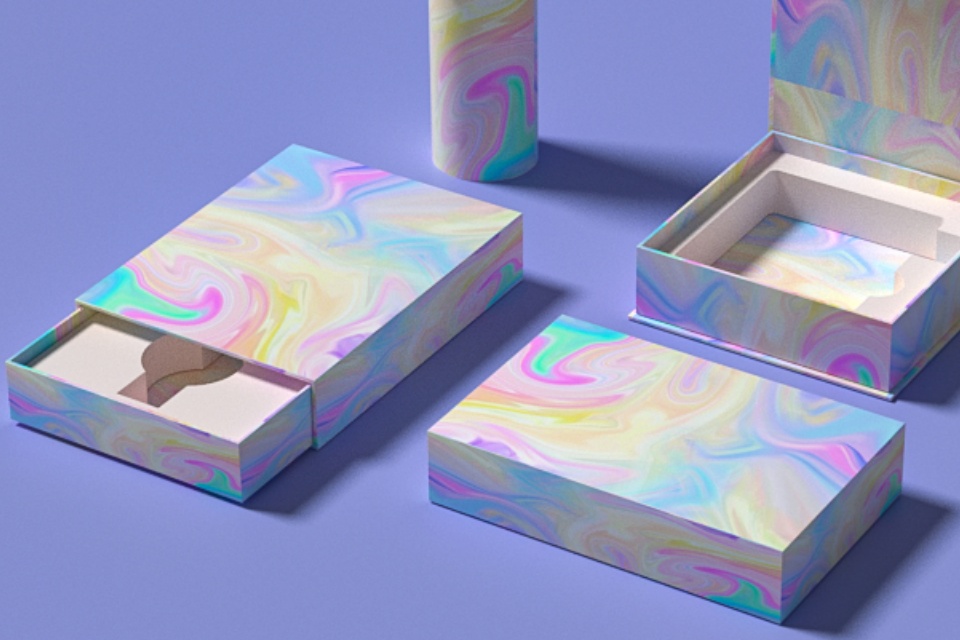

Magnetic Vape Cartridge Packaging Box and Rigid Drawer Box vs Simple Cartons

Now, branding. Your design team wants:

- Magnet flip lid

- Thick rigid box

- Soft-touch lamination

- Spot UV, foil, emboss, maybe hologram if they had a wild week

From a lifecycle view, this is basically boss level for material and process intensity. Magnets and multi-layer laminates make recycling harder, even when the outer board is paper.

On the Cheap Cannabis Packaging site you already see both sides of this:

- Magnetic Vape Cartridge Packaging Box with Foam Holder – high perceived value, strong unboxing moment.

- Cardboard Sliding Out Drawer Box for Vape Cartridge Packaging with Free Custom Service – still premium, but simpler, lighter, easier to flatten and recycle.

From an LCA angle, you don’t have to quit rigid boxes altogether. But you can:

- Use magnet boxes only for limited drops or gift scenes, not every everyday SKU.

- For mainline carts, choose slide-out drawer or child-lock paper boxes with EVA or paper insert.

- Keep printing smart: CMYK + maybe one foil, not five fancy finishes on every panel.

A lot of buyers quietly tell us:

“Our creative team love magnet box, but logistics hate it, and sustainability report hate it more.”

That’s exactly where lifecycle thinking saves you. You keep the brand effect, but move volume SKUs into simpler child-resistant structures that still look sharp in display.

How Zhibang and Cheap Cannabis Packaging Optimize Vape Cartridge Packaging Lifecycle

OEM/ODM Vape Cartridge Packaging, Bulk Orders and Real World Use Cases

On your site you position as a Reliable Manufacturer for Cannabis Packaging in China with cheap price, reliable service, and quality. You cover:

- Vape Cartridge Packaging – child-resistant boxes, slide-out drawers, magnet flip, private-label prints.

- Child Resistant Packaging – for carts, pods, edibles.

- Pre Roll Packaging – eco-friendly tubes and boxes.

- Paper Tube Packaging – more circular look and feel.

- Concentrate Container Packaging – rigid jars, child-safe outers.

That’s basically a full toolkit to adjust the lifecycle at every stage:

Table 2 – Brand pain points vs lifecycle-friendly vape packaging moves

| Brand / Buyer Pain Point | Lifecycle-Friendly Move | What Zhibang can do in OEM/ODM mode |

|---|---|---|

| “We need child resistant, but box feels too heavy and expensive.” | Shift to child-resistant paper drawer or button-lock slider with leaner board and simpler insert. | Re-engineer die-line, test lock function, run white dummy samples before mass run. |

| “Shelf space is tight, box too tall for 1 g carts.” | Shorter rigid drawer or tuck-end carton with snug EVA/paper insert. Better pallet density, less void. | Adjust inner cavity to your exact cart length, share 3D drawing, test on your cart samples. |

| “We want more sustainable story without killing our margins.” | Move from magnet box to rigid drawer for core SKUs, keep magnet only for special gift runs. | Offer two structures off same artwork: premium magnet gift box + lean everyday CRC slider. |

| “Ops team hate slow packing, line is choking.” | Simpler box that still hits compliance but is faster to load carts into. | Optimize insert shape, open angle, and friction so workers can drop carts in faster. |

Because you do customization, bulk wholesale, OEM/ODM, you’re not stuck with one “stock” box. You can tweak board grade, insert, coating, lock system, all inside one factory. That’s huge for lifecycle: every change is pre-agreed on the die-line, not hacked later.

A few real-world scenes where this matter:

- Multi-state brands – Different states, different labels and warning icons. One base structure, swap print layers. No need to reinvent the whole box every time.

- Big distro orders – When you scale from small batches to big PO’s, freight and warehousing start to hurt. A slimmer child-resistant box from Zhibang means more units per carton and less air in your containers.

- Sustainability-driven retailers – Some chains now ask about recyclability, FSC paper, or plastic reduction. Showing you moved to single-material paper drawer boxes or paper tube packaging is a very easy talking point in the buyer meeting.

Sometimes buyers say “it’s just a box”. On lifecycle analysis level, it’s not. It’s the piece that touches every step: sourcing, converting, logistics, retail, and trash can.

Conclusion: Lifecycle Thinking Makes Vape Cartridge Packaging Less Painful

When you look at Lifecycle Analysis Of Vape Cartridge Packaging Systems, a few things jump out:

- Most impact comes from materials and manufacturing, so structure and material choice are your first levers.

- End-of-life is messy because vapes are mixed waste (plastic + nicotine + electronics), so simpler, paper-dominant boxes help a bit instead of making it worse.

- Heavy magnet boxes and over-designed packs look cool but cost you in freight, storage, and LCA; slim child-resistant drawers and smart inserts balance brand and footprint.

If you already source from Cheap Cannabis Packaging / Zhibang, you’re half way there. You can talk lifecycle with the factory, not just “color and price”. Ask for:

- Leaner child-resistant vape cartridge packaging

- Smarter inserts and shorter formats for your carts

- Options in paper tube packaging and pre roll packaging that align with your sustainability story

It’s not about chasing a perfect score. It’s about making sure every new box you move into the market is a bit lighter, cleaner, and smarter than the last one – and still sells your oil.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory