-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Pre-roll Box Design And Manufacturing

Quick guide to pre-roll box design and manufacturing, from child-resistant and custom branding to eco-friendly materials and scalable OEM/ODM production.

You sell pre-rolls, not paper.

But if the box is wrong, everything else hurts – compliance, shelf life, margins, even your fill line mood.

Cheap Cannabis Packaging sits behind that whole problem as a Reliable Manufacturer for Cannabis Packaging in China, with bulk programs for Pre Roll Packaging, Child Resistant Packaging, Paper Tube Packaging, Pre Roll Packaging, Vape Cartridge Packaging, and Concentrate Container Packaging. Cheap Cannabis Packaging

Let’s walk through pre-roll box design and manufacturing the way buyers, ops people, and brand teams actually think about it.

Table of Contents

Pre Roll Packaging Design and Compliance

Before you fall in love with a pretty drawer box, you’ve got three boring but critical questions:

- Is it child resistant (CR) where needed?

- Can we fit all the legal copy?

- Will it protect aroma and structure?

On our site, CR shows up everywhere: certified sliders, push-lock child resistant pre-roll boxes, paper tubes with twist-lock tops. Most of them are built around PPPA / 16 CFR 1700 and ISO 8317 logic – in other words, they’re designed to pass proper child-resistant testing, not just “feel kinda tight.”

You also need space for:

- THC/CBD numbers, batch, net weight

- warnings and symbols

- QR codes and track & trace stuff

That’s why so many CR slider boxes and magnetic multipacks on your Pre Roll Packaging page have big, flat panels and clean lids. They’re not just “nice design”; they’re label real estate built in from the start.

Quick Table – From Pain Point To Pre Roll Box Move

| Buyer pain point | Design / manufacturing move | Pre-roll box style that fits | Where Cheap Cannabis Packaging + Zhibang help |

|---|---|---|---|

| “We keep failing CR checks.” | Lock in Child Resistant Packaging early, spec tested mechanisms (push-lock sliders, twist CR tubes), ask for test reports (PPPA / ISO 8317). | Certified CR pre-roll sliding boxes, CR slider push boxes, CR paper tubes. | Zhibang runs OEM/ODM with CR focus (test reports, stable tooling, repeatable locks). |

| “Our joints dry out or lose terps too fast.” | Pair CR with barrier thinking: liner choice, tight tray fit, fewer air voids. | Rigid multipack boxes with inserts, paper tubes with barrier liners. | Engineering team helps spec OTR/WVTR-friendly structures without overbuilding cost. |

| “We can’t fit all the warnings and still look premium.” | Use wide-front structures, clear hierarchy (brand > strain > net wt > warnings). | 5-pack / 7-pack sleeve boxes, magnetic clamshell, cigarette-style boxes. | Prepress + dieline support keeps artwork readable and compliant at print. |

| “Ops hates packing these things.” | Choose shapes that run fast: simple sliders, tidy inserts, easy-close lids. | CR sliders, drawer boxes with paperboard inserts, kraft cigarette-style packs. | Zhibang engineers design around line speed: tray fit, carton spec, AQL checks. |

If you treat that table like a mini checklist, you already think more like a packaging engineer than a logo person.

Pre Roll Packaging Materials and Box Types

Pre Roll Packaging Materials: Paperboard, Rigid Boxes, Paper Tubes

On your catalog and blog, three families show up again and again:

- Rigid and paperboard pre-roll boxes – sliders, magnetic clamshells, cigarette-style packs.

- Pre roll paper tube packaging – recycled fiber cylinders with liners and optional CR tops.

- Hybrid setups – pre-rolls in tubes, then tubes in an outer rigid or sleeve for “gift” tiers.

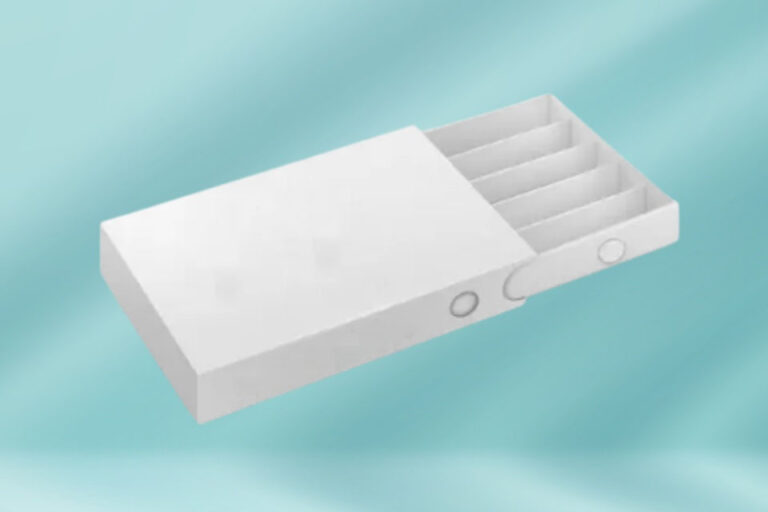

Paper ≠ flimsy here. Your CR slider multipack uses thick recycled paperboard plus art paper and food-grade dividers so joints don’t rattle and corners don’t crush during freight. For the 7-pack sleeve box, rigid paper plus a die-cut insert gives that “click into place” feel when people slide it open.

Real life usage scenes:

- Grab-and-go multipacks in dispensaries → slim sliders with clear strain callouts.

- Tourist / gift SKUs → magnetic drawer rigid boxes with matte lamination and foil logos.

- Value channel → kraft paper sliding drawer or cigarette-style boxes; honest, tough, no over-coating.

You don’t start from the box though. Your own guide says: start from the pre-roll size and count, then pick tray, then outer shell. That order cuts rework and dunnage, and it makes your costing meetings way less painful.

Child Resistant Pre Roll Packaging Design

CR is more than “add a stiff lid.”

On the site, CR shows up as:

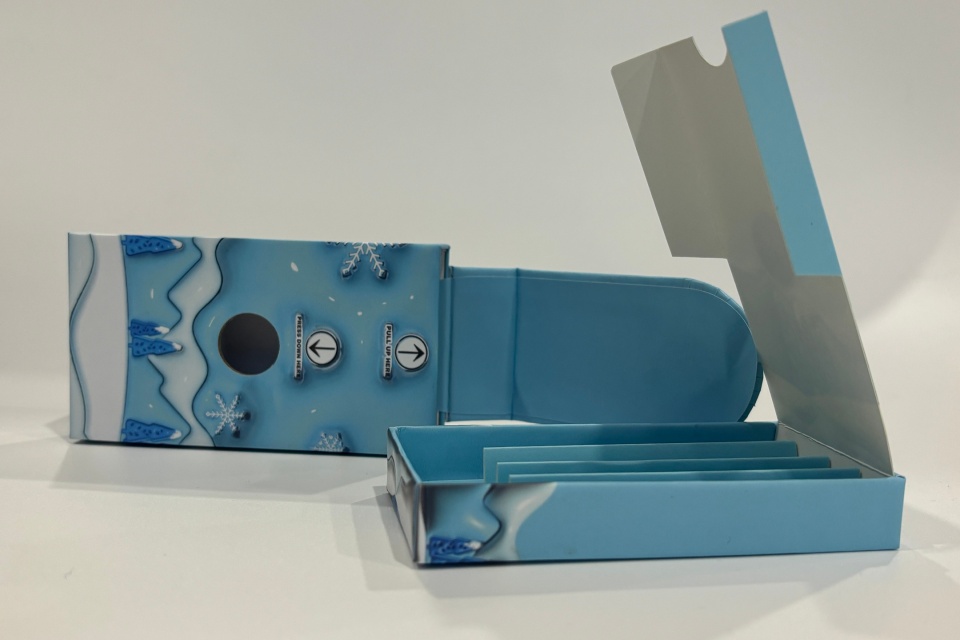

- Certified child-resistant pre-roll sliding boxes for 5-packs and similar.

- Push-lock CR slider boxes where you press and push to open.

- CR paper tubes using twist or press mechanisms but still mostly fiber.

Behind all that sits Zhibang, the factory side, working around ISO 8317 and PPPA 16 CFR 1700 testing, plus cannabis-specific panel tests.

The trick is to keep three things in line:

- Adults can open it without swearing.

- Kids can’t open it during CR testing.

- Lines can pack it at speed.

So when you brief a “new CR pre-roll slider,” you don’t only send artwork. You send cone size, count, preferred lock type, and any retail policy (for example, “needs tamper band over the drawer”). The Zhibang team then tunes tray depth, lock position, and paperboard GSM so the box passes lab tests and doesn’t jam on the line.

OEM/ODM Pre Roll Packaging Manufacturing Workflow

OEM/ODM Pre Roll Packaging Manufacturing Workflow

On paper, it looks simple. In reality, people usually skip steps and then yell at cartons later. Your own step-by-step guide lays it out pretty clean:

- Lock the pack size.

Single, 5-pack, 7-pack? This choice drives tray layout and shell size. - Pick safety level.

Child Resistant Packaging or standard? Local rules + retailer policy decide it. - Choose the structure.

Rigid box, magnetic drawer, CR slider, hexagon, or tube. Check drop tests, shipping, and how easy it is to grab a joint out. - Decide look & feel.

Matte, soft-touch, foil, spot gloss. Think about fingerprints, scuffing, and how it will look after a few days on shelf. - Select insert or tray.

Foam, paperboard, molded pulp. The goal: no crushed cones, no rattling, no bent tips. - Confirm labels & info.

SKU name, net weight, warnings, batch, QR. Space is not optional; compliance needs to be readable, not hidden in 5pt type. - Run a pilot batch.

Samples + small run. You literally pack real joints, shake the box, and walk it through your line. - Then scale to bulk wholesale.

This is where Zhibang as the manufacturer kicks in hard: ISO-backed QC, dieline control, stable color, carton spec that survives shipping.

It’s OEM/ODM in the real sense: you own the brand and specs, Zhibang keeps the machines, CR test logic, and QA humming in the background.

Cost-Effective Pre Roll Packaging Solutions For Dispensaries and Brands

You don’t need the fanciest spec for every SKU. You need the right box for the right retail job. Your blog and product pages already hint at three main lanes:

| Retail scenario | Recommended pre-roll box design | Why it works in practice |

|---|---|---|

| Dispensary “grab-and-go” shelf | 5-pack CR slider, bold front panel, clean sides for warnings. | Easy facings, safe for pockets/bags, simple restock. Helps lift basket size without changing store layout. |

| Tourist / gift tier | Magnetic drawer rigid pre-roll box or 7-pack sleeve with insert. | Feels premium, “open again” effect. Nice for limited strains or collab drops; good unboxing for social. |

| Value / price-sensitive | kraft paper sliding drawer or cigarette-style pre-roll boxes. | Honest look, low material spend, still sturdy. Works for big-volume, everyday SKUs and bulk wholesale. |

You can even mix lines: maybe premium 7-packs in rigid, everyday singles in paper tubes, and “value flight” multipacks in kraft sliders. Because Cheap Cannabis Packaging also runs vape, concentrate, tube and CR programs, you keep art systems aligned across everything, not random per SKU.

Ops language here is simple: less SKU chaos, faster fills, fewer damaged returns. Not sexy words, but they pay for themselves.

Sustainable Pre Roll Packaging and Biodegradable Options

The sustainability pressure is real. Distributors ask about recycled content, end consumers ask if they can toss the box in paper recycling, regulators look at plastics.

Your biodegradable pre roll packaging and recycled paper tube pieces basically say:

- Lean toward paper-first structures for pre-rolls – rigid boxes, sliders, tubes.

- Use multi-ply paperboard plus smart liners to stop crushed cones and scent bleed without flooding the design with plastic.

- Pick CR paper tubes and CR sliders that still pass tests but stay mostly fiber, so end-of-life looks better than clamshells.

There’s also the boring-but-key piece: test transit properly. Stack tubes with real fill weights, run through temperature and humidity swings, and see where it fails before you sign a big PO. That’s already baked into Zhibang’s QA style – transit checks, AQL, leak / seal thinking for higher-barrier items.

You dont need “perfectly green” overnight. You need better material choices, fewer mixed substrates, and CR systems that still support recycling and composting routes. One step each launch, not a giant reset every year.

Why Cheap Cannabis Packaging and Zhibang Make Pre-Roll Box Projects Easier

Under CheapCannabisPackaging.com sits Zhibang, the factory team focusing on:

- CR systems for joints, vapes, edibles.

- Bulk OEM/ODM runs across Pre Roll Packaging, Child Resistant Packaging, Paper Tube Packaging, Vape Cartridge Packaging, Concentrate Container Packaging.

- Real QC: ISO-style checks, CR testing support, color control, transit thinking.

So when you spec a new pre-roll box, you’re not just picking a shape. You’re plugging into a design + manufacturing system that already knows cannabis, knows CR standards, and speaks the same “ops pain” language you do.

That’s what makes pre-roll box design and manufacturing actually work in the field, not just in a nice render.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory