-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

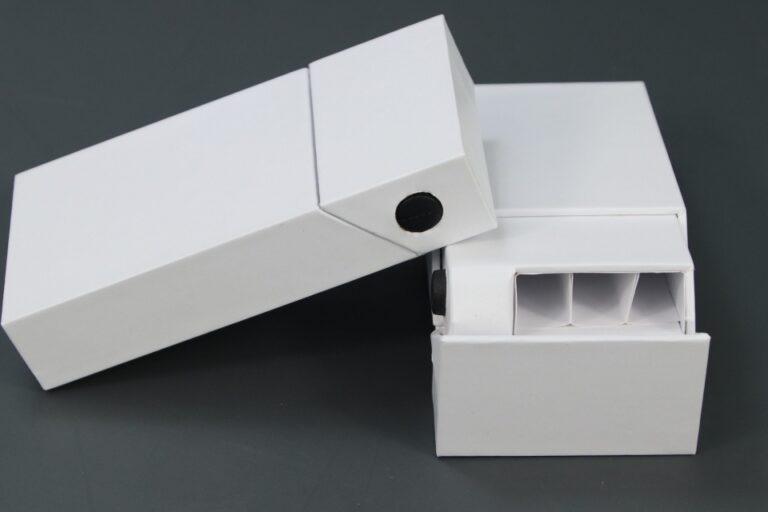

Squeeze-to-Open Child Resistant Boxes

Quick guide to squeeze-to-open child-resistant boxes: what they are, PPPA/ISO basics, real cannabis use cases, design knobs, and OEM/ODM wholesale options.

Short version: squeeze-to-open is a legit, testable child-resistant (CR) mechanism. It passes (or fails) on performance under PPPA / 16 CFR 1700 and ISO 8317, not on pretty drawings.

Table of Contents

Child-Resistant Packaging (CRP) under PPPA — 16 CFR 1700.15 & 1700.20

Squeeze-to-open sits squarely inside “special packaging” rules defined by the Poison Prevention Packaging Act. The law doesn’t bless a shape; it measures how hard kids fail to open and how reliably adults succeed. That’s the whole game.

- Child panel thresholds: ≥ 85% child-resistance before demonstration, ≥ 80% after demonstration.

- Adult panel (incl. seniors): usability must hit the prescribed success rate within tight time windows.

- Takeaway: your design passes if the panels say so. Not because it “looks CR.”

Squeeze-to-Open (two-point squeeze) — recognized CR mechanism

The squeeze action forces two coordinated hand motions (pinch + lift/pop). That dual-action is exactly why it frustrates young children, while adults read the tactile cues and open fast. With proper wall thickness and ribbing, it’s also repeatable through many re-closures—key for multi-dose formats.

ISO 8317:2015 — Reclosable Child-Resistant Packaging

If you’re shipping outside the U.S., or you serve global buyers, ISO 8317 is the mirror you’ll keep hearing about. Same spirit: child-resistant, adult-friendly, verified by panel testing. It also calls out “series” control—when you scale the same structure across sizes, the critical features (mechanism, materials, stiffness, closures) must stay consistent. Change those too much? Retest.

Usability for Senior Adults — PPPA Adult-Panel Metrics

CR is not “hard for everyone”; it’s hard for kids, intuitive for adults. The adult/senior panel in PPPA is your guardrail: if users with lower grip strength can’t open it fast, you fail. For squeeze-to-open, the knobs you tune are:

- Pinch force (N): too high = returns spike; too low = kids beat it.

- Texture & grip: micro-ribs and matte beats glossy slip.

- Visual instruction: arrows + “SQUEEZE” emboss keeps open times low.

- Re-close feedback: audible/tactile “click” so users know it sealed.

Tamper-Evident ≠ Child-Resistant

One is “shows if someone messed with it,” the other is “hard for kids to open.” Many cannabis SKUs need both. For squeeze-to-open, pair with a tear-band sleeve, label bridge, or shrink band to cover TE. Two jobs, two tools.

Field Scenarios (Cannabis) you actually meet

Let’s keep it real and use shop-floor language:

- Pre-roll multipack (5-pack, 10-pack): trays or pods inside a squeeze-to-open outer. Merchandises clean, no rattle if you spec the cavity right.

- Gummies / edibles: reclosable squeeze box avoids child easy-twist lids. Add a foil pouch liner for aroma control.

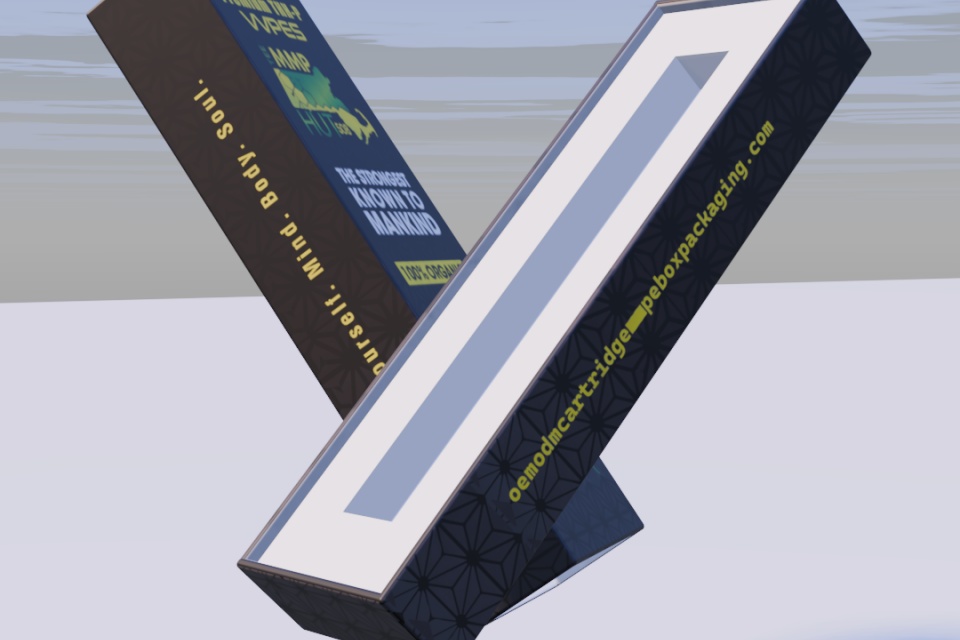

- Vape carts (510) + disposables: secondary squeeze box keeps needle-nose kids out while letting budtenders demo fast.

- Concentrates / shatter jars: glass jar stays primary; squeeze-box acts as secondary CR + billboard for compliance copy.

- Exit packaging: when regs allow, a generic squeeze-to-open shell that fits multiple unit cartons saves you from SKU creep.

- E-comm / DTC: specify wall thickness + corner radii to survive sortation; ISTA pre-screening reduces “burst in bag” complaints.

What buyers care about (pain points, solved)

- “I need CR that doesn’t kill fill speed.”

Squeeze structures are simple: no threads to line up, no torque windows. Pack-out crews love it. - “Retail wants easy demo, auditors want PPPA.”

One-hand squeeze demo takes 2 seconds; the PPPA/ISO framework gives your QA the receipts. - “We’re fighting unit costs and MOQs.”

Single-material PP bodies run well in high-cavitation molds. Also plays nice with bulk wholesale and OEM/ODM programs—exactly what we do at Cheap Cannabis Packaging. - “Brand wants quiet, minimal look.”

Flat faces, clean hinges, and in-mold text let you keep the billboard calm while staying compliant.

Argument Map (claims, proof, why it matters)

| Claim | Details | Why it matters | Source |

|---|---|---|---|

| Squeeze-to-open is a valid CR mechanism | Dual-action pinch prevents naïve single-motion opening; widely used in certified packs | You’re not “hacking” CR—you’re choosing a tested archetype | PPPA / 16 CFR 1700.15 & 1700.20; CPSC guidance |

| Compliance = performance, not shape | Pass/fail is set by child/adult panels and thresholds | Focus engineering on open force, cues, re-close, not cosmetic gimmicks | PPPA / 16 CFR |

| ISO 8317 aligns for global | Reclosable CR with series consistency rules | Cross-border buyers will ask for it; easier procurement sign-off | ISO 8317:2015 |

| CR ≠ tamper-evident | Different purposes, both often required | Avoid compliance gaps; reduces rework during audits | PPPA, ISO 8317 |

| Senior-friendly is mandatory | Adult panel success within defined time windows | Reduces complaint rate; safer user experience | PPPA / Adult-panel protocol |

| Single-material PP is recycling-friendly | PP (#5) bodies; no metal springs | Sustainability talking point without weird BOM | Industry practice & lab reports |

| State cannabis rules reference PPPA | Many states pull in 16 CFR 1700 for child-resistance | Your SKUs travel; one standard reduces headaches | State-level packaging regs aligning to PPPA |

Design knobs that actually move test results

- Squeeze window geometry: widen the “grip flats” and add micro-texture. Adults open faster; kids still fail because of coordination demand.

- Hinge & latch stiffness: consistent snap without creep; watch PP grade MFR so it doesn’t soften in hot transport.

- Instruction emboss: bold “SQUEEZE HERE” + arrows. No wall of copy, just the cue.

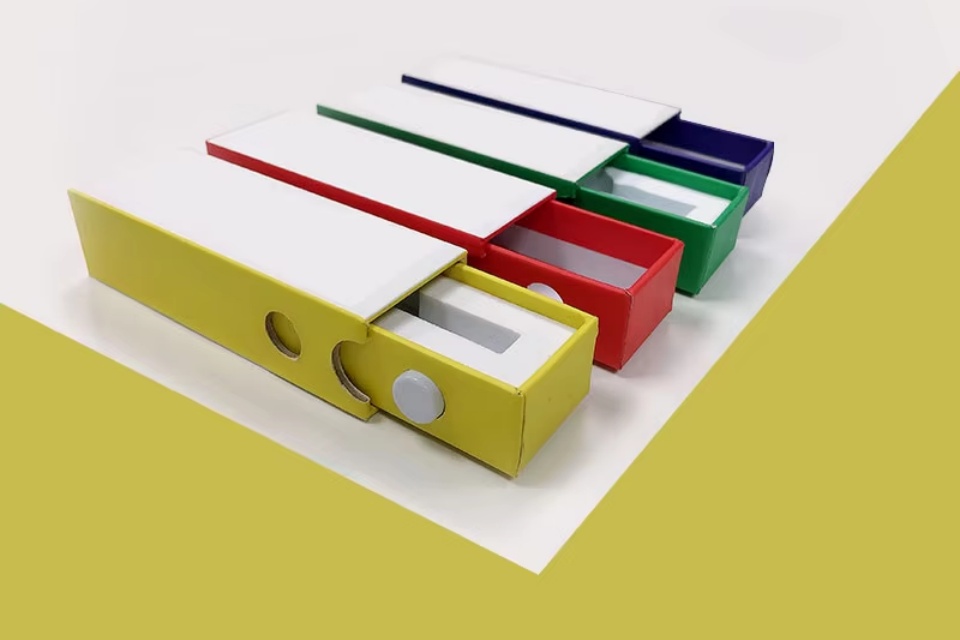

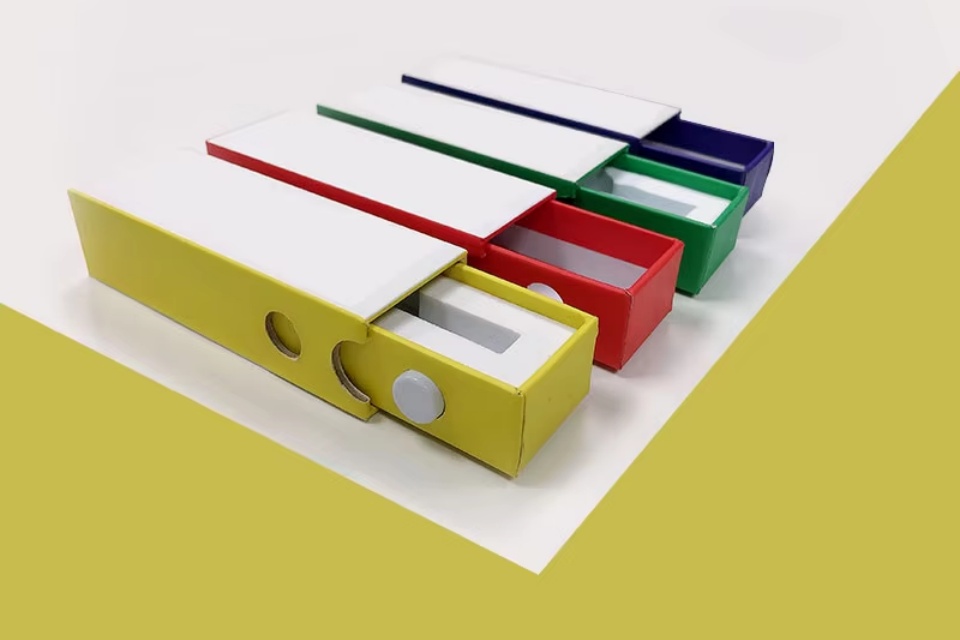

- Color coding: dark body + light arrows test better in quick-look tasks (yep, tiny thing, big effect).

- Re-close click: audible is nice, tactile is king—take the noise if it boosts confidence.

- TE bridge add-ons: perforated label spanning lid/base or shrink neck; cheap, audit-proof.

Where Cheap Cannabis Packaging fits (and why us)

We’re a Reliable Manufacturer for Cannabis Packaging in China focused on value without the drama. Our SEO line says it plainly—and it’s also how we operate on the floor:

- What we sell: Child Resistant Packaging, Concentrate Container Packaging, Paper Tube Packaging, Pre Roll Packaging, Vape Cartridge Packaging.

- How we sell: custom, bulk, OEM/ODM, and wholesale.

- Why it helps you: fewer vendors, faster PO cycle, tighter color/fit tolerance across matching families (your brand line actually looks like a line).

- CR squeeze-to-open options: standard footprints ready to kit, or custom sizes so your cartons don’t rattle like maracas.

Browse the category here:

Child Resistant Packaging — https://cheapcannabispackaging.com/product-category/child-resistant-packaging/

Quick buyer checklist

- Target 16 CFR 1700 / ISO 8317 performance, not “looks CR.”

- Request child/adult panel certificates in the doc pack.

- Specify pinch force window (vendor to propose + validate).

- Require instruction emboss artwork in CAD, not “we’ll add later.”

- Add TE bridge (label or band) if SKU demands it.

- Lock PP grade (MFR, impact) + masterbatch to stop color drift.

- Ask for series control: same latch/hook across sizes = fewer retests.

- Run a small pilot fill; check open/close fatigue after 20 cycles.

Sample spec snapshot (for a squeeze-to-open box)

- Material: PP (polypropylene), mono-material body + hinge

- Closure: twin-point squeeze tabs + snap latch

- Finish: fine-matte outside for grip; gloss inside for clean pour

- Emboss: “SQUEEZE HERE” + directional arrows on both flats

- TE option: shrink band or label bridge (die-line supplied)

- Colors: brand pantone masterbatch; low migration inks for any print

- Tests: PPPA child/adult panel; ISO 8317 where applicable; transit pre-screen (carton)

Common pushbacks (and how we handle)

- “My seniors can’t open it.” → lower pinch force slightly, add micro-ribs; keep latch geometry so child metrics don’t tank.

- “Too plain for our brand.” → in-mold texture, deboss logo on lid, contrast arrows—stays compliant, looks premium.

- “MOQ too high.” → suggest shared tooling footprints with custom color + label bridge; later move to dedicated mold when velocity proves out.

- “Ops says slow.” → tray-feed lines love these; no torque spec, no cross-thread. We validate with your pack-out SOPs, not just lab talk.

Sources

- PPPA / 16 CFR 1700.15 & 1700.20 (CPSC) — performance requirements and panel testing.

- ISO 8317:2015 — reclosable child-resistant packaging, requirements and testing.

- CPSC PPPA training & guidance — terminology, adult-panel emphasis, “child-resistant” vs “child-proof.”

- State cannabis packaging regulations — broad alignment with 16 CFR 1700 for child-resistance.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory