-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Step-By-Step Guide To Designing Custom Paper Tube Packaging

Quick guide to custom cannabis paper tube packaging: choose structure, CR features, and eco materials to boost shelf impact and support bulk OEM/ODM.

This guide walks you, step by step, through custom cannabis paper tube packaging the way we handle it behind CheapCannabisPackaging.com and Zhibang in China – where people actually buy in bulk, OEM/ODM, not just “one cute mockup”.

Table of Contents

Why Custom Cannabis Paper Tube Packaging Matters

For cannabis brands, paper tube packaging isn’t just a “nice extra” anymore. It has to tick four boxes at once:

- child-resistant (PPPA / 16 CFR 1700.20, ISO 8317),

- shelf impact,

- aroma protection,

- and a real sustainability story.

On the sustainability side, one big survey shows 60–70% of consumers are willing to pay more for sustainable packaging, and many see paper / paperboard as one of the most eco-friendly substrates. Another recent report found over 80% of buyers would pay extra for sustainable packaging, even with higher prices in the market.

So if your tube is paper-based, recyclable, and clearly labeled as eco, you are not just doing the right thing. You are matching what the market already expect.

Data Snapshot: Sustainable Packaging and Paper Tubes

| Insight from recent reports | Data point (rounded) | What it means for cannabis paper tubes |

|---|---|---|

| Consumers willing to pay more for sustainable packaging | ~60–80% of surveyed buyers | A recycled-board paper tube with clear eco messaging is easier to defend than a plain plastic doob tube. |

| Consumers that choose products because of sustainable packaging | ~70%+ in some studies | If your tube tells a “less plastic, recyclable” story on-pack, it can push purchase, not just protect product. |

| Consumers that rank recyclability as top sustainability feature | #1 characteristic | Paperboard tubes with simple liners beat complex multi-material packs that confuse recycling. |

That is the business argument. Now let’s go step by step.

Step 1 – Start Custom Paper Tube Packaging From Product and Compliance Goals

Before you touch a dieline, answer three boring but critical questions:

- What is inside?

- single pre-roll, multi-pack, 510 vape cart, disposable vape, or cannabis flower jar?

- Where will it sell?

- state rules, maybe EU, maybe both. Each region has its own CR and label rules.

- What must this tube survive?

- drop tests, shipping, humidity, maybe e-commerce.

On your own Paper Tube Packaging category page we already split scenes pretty clearly: CR paper tubes for vape carts, child-resistant pre roll tubes, cannabis flower tubes, and slim cylinders for vapes. That’s exactly how buyers think in real life.

If you skip this step and jump straight to “nice artwork”, you’ll redo everything once compliance or filling line say “nope”.

Step 2 – Choose Paper Tube Structure and Size For Cannabis Brands

Now you lock the structure and dimensions. This is the skeleton.

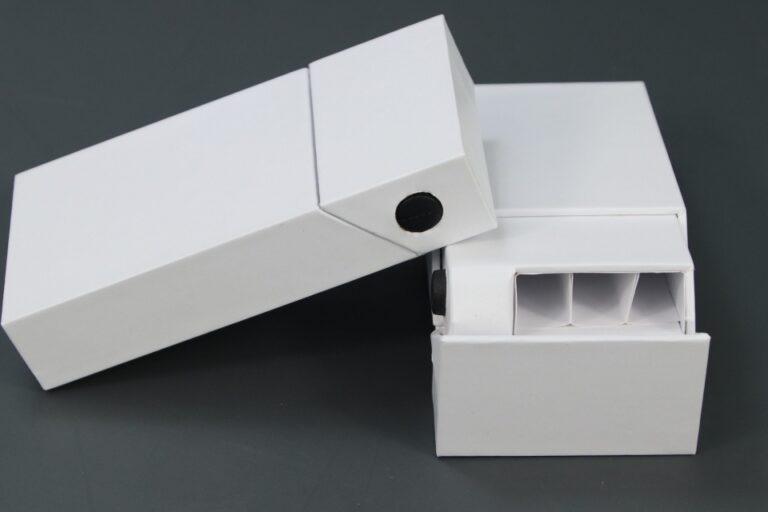

Typical structures you already run at Zhibang:

- classic telescope tube (lid + base),

- twist-to-unlock CR tubes,

- press-button child-resistant paper tubes,

- long slim tubes for vape pens,

- wider cylinders for cannabis flower or jars.

Here you talk boring stuff like OD / ID, wall height, insert depth, but this is where you kill later headaches like “cart rattling” or “cones crushed in transit”.

Summary Table: Paper Tube Packaging Choices By Cannabis Format

| Cannabis format | Typical paper tube type (from your catalog) | CR / insert setup | Main pain points solved |

|---|---|---|---|

| 510 vape cartridge | CR Paper Tube for Vape Cart, CR Child Resistant Paper Tubes | Press-button or twist lock + EVA foam insert holding the glass cart | Protects fragile glass, stops oil leaks hitting the wall, keeps kids out while staying panel-test friendly. |

| Vape pen / disposable | Slim Long Paper Cylinder Tube for Vape Pen | Rigid tube with tight fit, sometimes simple friction or optional CR top | Stops devices bending in transit, gives more vertical billboard space on shelf, keeps cables or leaflets together. |

| Pre-rolls (single / multi) | Child Resistant Pre Roll Paper Tubes, Twist CR Paper Tubes | CR closure + liner or collar to hold cones | Avoids crushed tips, controls odor bleed in dispensary, more “grown-up” look than plastic doob tubes. |

| Flower / small jar | Cannabis Flower Paper Tubes / Marijuana Paper Tubes | Often outer premium tube over jar, CR either on inner jar or tube | Adds shelf presence, gives extra real estate for warnings, QR, and strain story without changing jar tooling. |

Once diameter and height are frozen, the dieline is not random anymore. It is a technical drawing tied to real tooling and CR geometry.

Step 3 – Materials, Wall Thickness and Barrier Layers In Cannabis Paper Tube Packaging

Next, you pick board, liner, and insert. For cannabis, you juggle three things:

- eco story,

- product protection,

- and CR lock strength.

Best practice in your own CR tube guides looks like this:

- Outer tube – FSC-type paperboard, kraft or white, thick enough (up to 800 gsm on some SKUs) to hold the child-resistant button or twist groove without deforming.

- Inner liner – PE coat, foil, or glassine depending on oil, moisture, and aroma. Glass and concentrates need different barrier than a dry pre-roll.

- Insert – EVA foam, molded paper, or paperboard collar to stop things moving and add a bit of controlled resistance.

From sustainability research, consumers rank paperboard and paper as among the most sustainable packaging materials, often above laminated foil. If you keep plastic bits and heavy foil to a minimum, your ESG slide later is much easier to defend.

Step 4 – Child-Resistant Paper Tube Packaging (16 CFR 1700.20 / ISO 8317)

Now the “black talk” part: CR logic. For cannabis, regulators care about one thing:

most small kids can’t open, most adults (including seniors) can.

Your own CR paper tube blog breaks this into very clear steps:

- Panel tests under 16 CFR 1700.20 – kids under about five try to open; most must fail inside a timed window.

- Adult panel – adults 50–70 open and reclose; most must succeed.

- ISO 8317 / EN 862 – similar logic for EU markets.

If a supplier can’t explain that test flow in simple words, you probably don’t want them touching your CR SKUs.

Child-Resistant Paper Tubes For Vape Cartridge Packaging

Look at your CR vape cartridge paper tubes:

- 2×8 cm and 3×12 cm formats,

- locking button built into the rigid paperboard wall,

- EVA foam bed for the cart,

- offset print + matte lamination + foil details.

This kind of structure is made for the classic “press + pull” adult motion. Kids see a smooth cylinder with one tiny button. For them it is confusing. For experienced users it is simple muscle memory after the first try. That is exactly what CR protocols want.

Child-Resistant Paper Tubes For Pre Roll Packaging

For pre-rolls, many brands go for:

- twist-to-open CR tubes for singles,

- wider CR cylinders for 5–10 stick sets,

- sometimes inner odor-control liner plus foam or paper collars.

Here you also fight planogram chaos. Matching tube heights and diameters across SKUs makes life easier for MSOs and chain buyers. It sounds boring, but when your tubes line up on a 3-foot shelf, the whole set look controlled and premium instead of random.

Step 5 – Artwork, Dielines and Shelf Appeal On Paper Tube Packaging

Once structure and CR story are locked, the designers finally get to play. But even this step has rules.

From your own “Maximizing Shelf Appeal With Custom Paper Tube Packaging” post, a few levers show up again and again:

- 360° full-bleed printing so the tube looks good from any angle.

- Matte or soft-touch wrap + foil or spot UV for a “feel in hand” that plastic can’t match.

- Consistent height per product family for clean shelf lines.

- Clear zones for THC icons, age marks, warning blocks, QR codes so compliance text doesn’t fight with your logo.

On the technical side, the dieline from the factory is not optional:

- you stay inside safe zones,

- you add enough bleed,

- you keep key text away from the CR button or twist area,

- images stay at real print resolution.

If you drop random art on a guessed template, the press can run, but then your logo may half sit on a seam or warning text land exactly over the button. Seen that too many times.

Step 6 – Prototypes, Testing and OEM/ODM Paper Tube Packaging With Zhibang

Last step before bulk: make samples, beat them up, and then lock the spec.

From factory side at Zhibang, a typical paper tube project runs like this:

- You send rough dimensions, units per tube, and where you sell (states, countries).

- We suggest tube diameter, height, board thickness, liner, insert, and CR structure if needed.

- Dieline drops with marked zones for warnings, THC icons, and TE labels.

- We run white samples (structure only) and printed samples for color and finish.

- You do real-world checks:

- does the tube run on your line or everything hand-pack?

- do budtenders and older customers open it without swearing?

- do tubes survive basic drop and ship tests?

Behind the scenes, the factory side cares about things like:

- AQL sampling so you don’t get a container full of tubes that don’t close right,

- Delta-E color tolerance so sativa / hybrid / indica variants still look like one family,

- MOQ tiers and line changeover time, so your launch plan doesn’t die on press schedule.

Zhibang has been doing bulk cannabis packaging (child resistant packaging, paper tubes, pre-roll, vape, concentrate containers) since 2011, so this is not theory for us. You bring SKU list and brand; we bring tubes, CR systems, and a production team that actually reply your emails. Sometimes with small grammar mistake, but still.

Final Thoughts: Make Paper Tube Packaging Work Like A Silent Sales Rep

If you follow the steps in order – goals → structure + size → materials → CR logic → artwork → samples – your custom paper tube packaging doesn’t just “hold product”. It:

- keeps kids out while adults get in,

- protects aroma and oil,

- tells a simple eco story,

- cleans up your planogram,

- and quietly supports higher perceived value without shouting.

You don’t have to redesign your whole lineup in one shot. Start with one pre-roll line or one vape range in tubes, watch how budtenders and customers react, then scale what works. When you’re ready for bigger runs, OEM/ODM, or new CR structures, Zhibang is sitting behind Cheap Cannabis Packaging ready to argue about OD, inserts, and panel tests with you all day.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory