-

Gushu Industrial Zone Xixiang Street, Bao'an District, Shenzhen

Step-By-Step Guide To Using Custom Printing On Vape Cartridge Packaging

Custom vape cartridge packaging, explained step by step: choose structure, prep dielines, pick printing/finishes, test prototypes, and lock QC for bulk runs.

If you sell carts, you already know this: the product is small, the shelf is loud, and one tiny mistake (wrong dieline, scuffed ink, unreadable warning panel) can turn into delays, rework, or a bad first impression. So yeah—custom printing on Vape Cartridge Packaging isn’t just “make it pretty.” It’s a system for brand trust, compliance, and smoother wholesale.

We build cannabis packaging in China for bulk buyers and distributors—child-resistant packaging, concentrate container packaging, paper tubes, pre-roll boxes, and vape cartridge packaging—with OEM/ODM and wholesale runs. That’s the lane. Now let’s walk the process like you’d actually do it in real life.

Table of Contents

Quick Argument Map For Custom Printing On Vape Cartridge Packaging

| Argument title (use as your section headers) | What you actually do | Real pain it solves (industry talk) | Source |

|---|---|---|---|

| Start With Buyer + Compliance For Vape Cartridge Packaging | lock target buyer + selling region rules before design | “pretty box” that fails review, warning text conflict, reprint hell | CheapCannabisPackaging internal workflow + FDA/CPSC/ISO references |

| Structure First: Vape Cartridge Packaging Box Style + Insert | choose structure, insert, closure before graphics | cracked carts, rattling, returns, chargebacks | Packaging production best practice + insert/divider practice |

| Dieline Setup For Custom Printing | build dieline, bleed, safe zone, glue/no-print areas | cut-off text, misfold, artwork hits lock tabs | Prepress standard (dieline/bleed/safe zone) |

| Artwork Layers: Brand, SKU, Warning, Batch | separate layers + plan future edits | SKU explosion, fast label changes, compliance edits | CheapCannabisPackaging internal workflow |

| Printing Method: CMYK, Pantone, VDP | match method to MOQ + SKU count + variable data | color shift, slow lead time, inconsistent runs | Print production best practice |

| Finishes: Lamination, Spot UV, Foil, Emboss | pick 1–2 finishes to highlight key elements | scuffing, cheap feel, shelf gets you ignored | Packaging finishing best practice |

| Prototyping + Stress Testing | open/close cycles, drop test, humidity, scan test | “looks good on screen” but fails in hand | QA practice (sampling + stress tests) |

| Mass Production QC: Golden Sample + AQL | keep golden sample, define defect rules, do spot checks | run-to-run drift, color mismatch, customer complaints | Factory QC practice |

| Post-Launch Iteration For Vape Cartridge Packaging | use feedback loop, adjust inserts + print + copy | repeat issues, rising support tickets, wasted stock | Ops best practice |

Note: Regulations change by market. Don’t treat this as legal advice. Use it as a build checklist, then verify your local rules.

Start With Buyer + Compliance For Vape Cartridge Packaging

Before you open Illustrator, answer three blunt questions:

- Who’s buying? Dispensary shopper, online DTC, or a wholesaler placing repeat POs?

- Where’s it sold? Different markets = different warning requirements.

- What’s the “shelf moment”? Bright retail lighting? Counter display? Delivery box unboxing?

Here’s the trick: if you skip this step, you usually end up redesigning later. And redesigns feel cheap, even when the printing is expensive.

Practical scenario:

You sell a “live resin” cart line to dispensaries. The budtender grabs it fast. If your strain name is small, or the warning block fights the logo, your SKU gets skipped. Simple as that.

Structure First: Vape Cartridge Packaging Box Style + Insert

For Vape Cartridge Packaging, the structure is half the product experience. Pick these early:

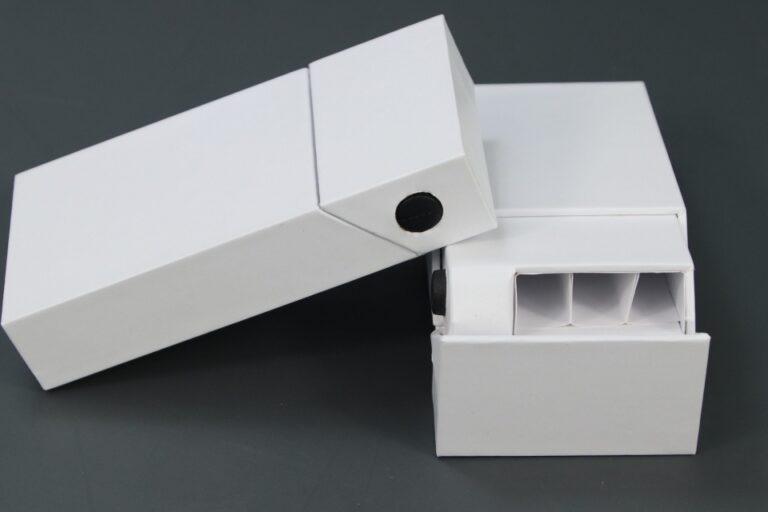

- Box style: tuck end, drawer, magnetic (less common for carts), or lock style

- Insert type: foam, paperboard insert, blister, molded tray (depends on positioning)

- Child-resistant needs: if your market requires CR, design it into the structure, not as an afterthought

Industry talk you’ll hear from buyers:

- “Carts are rattling in transit.”

- “Insert is too tight, customers fight it.”

- “Box pops open in shipping.”

Those are structure problems, not design problems.

Dieline Setup For Custom Printing On Vape Cartridge Packaging

This is where most packaging projects get messy.

Your dieline should clearly mark:

- Cut line / crease line

- Bleed (extra background area so you don’t get white edges)

- Safe zone (keep text/logos away from trim and folds)

- Glue zones / no-print areas (ink + glue = headaches)

- Lock tabs / child-resistant mechanisms (do not crowd these)

If you treat the dieline like “just a template,” you’ll pay for it. The press doesn’t care about your feelings.

Artwork Layers For Vape Cartridge Packaging: Brand, SKU, Warning, Batch

Build the file like you expect change. Because changes will happen.

Layer your artwork like this:

- Background + base color

- Brand visuals (logo, pattern, hero graphic—ok not that word, I mean main graphic)

- SKU info (strain, flavor, potency range text)

- Compliance/warning panel

- Variable data (batch, QR, serial, barcode)

Why? When you add new SKUs, you don’t want to touch the whole layout. You just swap the SKU layer and keep everything stable.

Printing Method For Custom Vape Cartridge Packaging: CMYK, Pantone, VDP

Pick printing based on how you sell, not based on what looks cool on a sample photo.

- Many SKUs, smaller runs: digital can move faster and supports easy updates

- Large wholesale runs: offset can be more consistent at scale

- Need unique QR/serial per unit: ask for VDP (variable data printing)

Pain point this avoids: color drift.

If your “brand green” turns into “almost green” across batches, distributors notice. They may not say it nicely.

Also, if you need tight brand color, ask for Pantone matching (or a defined color target). You’ll get fewer surprises.

Print Finishes For Vape Cartridge Packaging: Lamination, Spot UV, Foil, Emboss

Finishes are like seasoning. A little makes it better. Too much ruins the meal.

Common finishes that work well for carts:

- Matte lamination (premium feel, better scuff resistance)

- Soft-touch lamination (nice hand feel, but can show fingerprints)

- Spot UV (highlight logo or strain name)

- Foil stamping (premium cue, use carefully)

- Emboss/deboss (texture without shouting)

Rule of thumb: pick 1–2 finishes that support the story. Don’t stack effects just to stack them.

Prototyping + Stress Testing For Vape Cartridge Packaging

This is the “save yourself” step.

Test the sample like a buyer would:

- Open/close it 50–100 times (yeah, it’s boring)

- Do a simple drop test (desk height)

- Rub test (does ink scuff off?)

- Humidity check (does paper warp?)

- Barcode/QR scan test (retail scanners are picky)

If the box looks amazing but fails scanning, you get retail friction. That kills reorder vibes real quick.

Mass Production QC For Custom Printing: Golden Sample + AQL

If you’re ordering wholesale, don’t rely on “it should be fine.”

Use:

- Golden sample (approved reference sample kept for the full run)

- AQL sampling (a standard sampling method factories use for defect control)

- Defined defect rules: color tolerance, scratches, misregistration, glue issues, die-cut drift

This prevents the classic problem: first cartons look great, middle cartons drift, last cartons… you dont wanna see them.

Post-Launch Iteration For Vape Cartridge Packaging

The smartest brands treat packaging like a living system.

After launch, track:

- returns tied to damage

- complaints like “hard to open” or “ink rubbed off”

- distributor feedback on shelf readability

- SKU expansion speed (how fast you can spin new variants)

Then adjust structure, insert fit, copy placement, and print method. Small tweaks compound over time.

Where Zhibang Fits In (Real Business Value, Not Fluff)

When you scale packaging—especially OEM/ODM and bulk wholesale—the real bottleneck isn’t ideas. It’s execution: dielines, sampling, version control, and consistent QC.

That’s where teams like Zhibang can help you move cleaner: tighter spec sheets, faster SKU rollouts, and fewer “wait… which file is final?” moments. It’s not magic. It’s just grown-up operations.

Closing Take

Custom printing on Vape Cartridge Packaging works best when you treat it like a production pipeline, not a one-time art project. Start with buyer + compliance, lock structure, respect the dieline, keep layers clean, choose the right print method, test the sample hard, then manage QC like you mean it.

Comments

ASTM D3475 biodegradable pre roll packaging Bulk Wholesale Packaging cannabis branding cannabis packaging cannabis packaging compliance cannabis packaging manufacturer cannabis packaging wholesale Cheap Cannabis Packaging child-resistant child-resistant packaging child resistant cannabis packaging child resistant packaging child resistant pre roll packaging China packaging manufacturer Concentrate Container Packaging concentrate containers custom cannabis packaging custom pre-roll packaging custom pre roll boxes custom vape boxes Dispensary Packaging eco friendly packaging ISO 8317 marijuana packaging OEM/ODM OEM/ODM cannabis packaging OEM/ODM Wholesale OEM cannabis packaging OEM ODM Cannabis Packaging OEM ODM Packaging paper tube packaging pre-roll packaging Pre Roll Packaging sustainable cannabis packaging Sustainable Packaging Sustainable Vape Packaging tamper-evident Tamper-Evident Packaging TPD compliance Vape Cartridge Boxes vape cartridge packaging wholesale cannabis packaging Zhibang Zhibang China factory